Page 140 - Structural Steel Designers Handbook AISC, AASHTO, AISI, ASTM, and ASCE-07 Design Standards

P. 140

Brockenbrough_Ch03.qxd 9/29/05 5:05 PM Page 3.72

CONNECTIONS

3.72 CHAPTER THREE

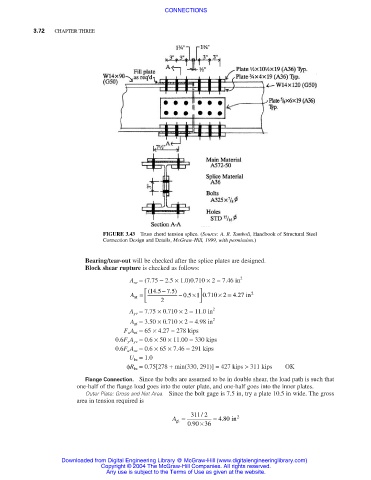

FIGURE 3.43 Truss chord tension splice. (Source: A. R. Tamboli, Handbook of Structural Steel

Connection Design and Details, McGraw-Hill, 1999, with permission.)

Bearing/tear-out will be checked after the splice plates are designed.

Block shear rupture is checked as follows:

A nv = (7.75 − 2.5 × 1.0)0.710 × 2 = 7.46 in 2

− . ) 5

14

A = (.5 7 − . 05 ×1 0 .710 2 in 2

×= . 4 27

nt

2

A gv = 7.75 × 0.710 × 2 = 11.0 in 2

A gt = 3.50 × 0.710 × 2 = 4.98 in 2

F u A nt = 65 × 4.27 = 278 kips

0.6F y A gv = 0.6 × 50 × 11.00 = 330 kips

0.6F u A nv = 0.6 × 65 × 7.46 = 291 kips

U bs = 1.0

φR bs = 0.75[278 + min(330, 291)] = 427 kips > 311 kips OK

Flange Connection. Since the bolts are assumed to be in double shear, the load path is such that

one-half of the flange load goes into the outer plate, and one-half goes into the inner plates.

Outer Plate: Gross and Net Area. Since the bolt gage is 7.5 in, try a plate 10.5 in wide. The gross

area in tension required is

A = 311 2 / = 480 in 2

.

gt

090 × 36

.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.