Page 161 - Structural Steel Designers Handbook AISC, AASHTO, AISI, ASTM, and ASCE-07 Design Standards

P. 161

Brockenbrough_Ch03.qxd 9/29/05 5:05 PM Page 3.93

CONNECTIONS

CONNECTIONS 3.93

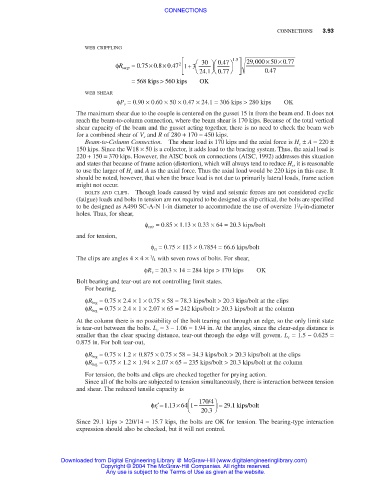

WEB CRIPPLING

. 15 . 29 000 50 0 77

×

,

× .

+

2

.

φR wcp = 075 08 047 13 30 047

× .

× .

24 1 . 077 047

.

.

>

= 568 kips 560 kips OK

WEB SHEAR

φP v = 0.90 × 0.60 × 50 × 0.47 × 24.1 = 306 kips > 280 kips OK

The maximum shear due to the couple is centered on the gusset 15 in from the beam end. It does not

reach the beam-to-column connection, where the beam shear is 170 kips. Because of the total vertical

shear capacity of the beam and the gusset acting together, there is no need to check the beam web

for a combined shear of V s and R of 280 + 170 = 450 kips.

Beam-to-Column Connection. The shear load is 170 kips and the axial force is H c ± A = 220 ±

150 kips. Since the W18 × 50 is a collector, it adds load to the bracing system. Thus, the axial load is

220 + 150 = 370 kips. However, the AISC book on connections (AISC, 1992) addresses this situation

and states that because of frame action (distortion), which will always tend to reduce H c , it is reasonable

to use the larger of H c and A as the axial force. Thus the axial load would be 220 kips in this case. It

should be noted, however, that when the brace load is not due to primarily lateral loads, frame action

might not occur.

BOLTS AND CLIPS. Though loads caused by wind and seismic forces are not considered cyclic

(fatigue) loads and bolts in tension are not required to be designed as slip critical, the bolts are specified

to be designed as A490 SC-A-N 1-in diameter to accommodate the use of oversize 1 / 4-in-diameter

1

holes. Thus, for shear,

φ rstr = 0.85 × 1.13 × 0.33 × 64 = 20.3 kips/bolt

and for tension,

φ rt = 0.75 × 113 × 0.7854 = 66.6 kips/bolt

3

The clips are angles 4 × 4 × / 4 with seven rows of bolts. For shear,

φR v = 20.3 × 14 = 284 kips > 170 kips OK

Bolt bearing and tear-out are not controlling limit states.

For bearing,

φR brg = 0.75 × 2.4 × 1 × 0.75 × 58 = 78.3 kips/bolt > 20.3 kips/bolt at the clips

φR brg = 0.75 × 2.4 × 1 × 2.07 × 65 = 242 kips/bolt > 20.3 kips/bolt at the column

At the column there is no possibility of the bolt tearing out through an edge, so the only limit state

is tear-out between the bolts. L c = 3 – 1.06 = 1.94 in. At the angles, since the clear-edge distance is

smaller than the clear spacing distance, tear-out through the edge will govern. L c = 1.5 − 0.625 =

0.875 in. For bolt tear-out,

φR brg = 0.75 × 1.2 × 0.875 × 0.75 × 58 = 34.3 kips/bolt > 20.3 kips/bolt at the clips

φR brg = 0.75 × 1.2 × 1.94 × 2.07 × 65 = 235 kips/bolt > 20.3 kips/bolt at the column

For tension, the bolts and clips are checked together for prying action.

Since all of the bolts are subjected to tension simultaneously, there is interaction between tension

and shear. The reduced tensile capacity is

170 4

/

×

.

.

φ ′= 113 64 1 − 20 3 = 29 1 kips/bolt

r

t

.

Since 29.1 kips > 220/14 = 15.7 kips, the bolts are OK for tension. The bearing-type interaction

expression should also be checked, but it will not control.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.