Page 126 - Sustainability in the Process Industry Integration and Optimization

P. 126

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 103

Natural Gas

Coal Fuel Oil

Current: 250.0 Current: 55.4

[50.0; 250.0] [40.0; 180.0] GT

HRSG 18 MW

Boiler 1 Boiler 2 Air

Current: 208.4 Current: 28

[115.0; 335.0]

Current: 105.0

VHP (101 bar abs.)

[60.0; 165.0]

Current: 15.0 T4 Current: 59.5 T6 20.0

[15.0; 75.0] [15.0; 65.0] 0.0

HP (41 bar abs.)

Current: 90.0 Current: 40.9

T5 54.5

[30.0; 9.0] [30.0; 70.0] 0.0

MP (15 bar abs.)

0.0

Current: 20.0 Current: 108.0 55.9

[20.0; 20.0] T7 [60.0; 150.0] 0.0

LP (3 bar abs.)

LP Vent

CW

0.073 bar abs. Current: 75.0 128.0

[40.0; 75.0]

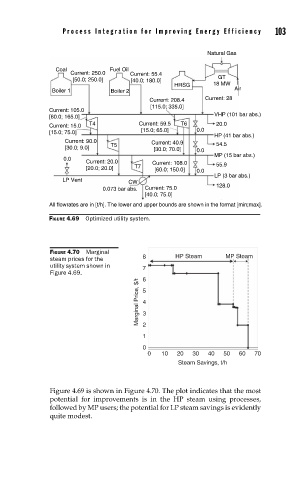

All flowrates are in [t/h]. The lower and upper bounds are shown in the format [min;max].

FIGURE 4.69 Optimized utility system.

FIGURE 4.70 Marginal

steam prices for the 8 HP Steam MP Steam

utility system shown in 7

Figure 4.69. 6

Marginal Price, $/t 5

4

3

2

1

0

0 10 20 30 40 50 60 70

Steam Savings, t/h

Figure 4.69 is shown in Figure 4.70. The plot indicates that the most

potential for improvements is in the HP steam using processes,

followed by MP users; the potential for LP steam savings is evidently

quite modest.