Page 122 - Sustainability in the Process Industry Integration and Optimization

P. 122

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 99

as unaccountable steam usage. These additional requirements have

to be considered when analyzing or designing the site’s utility

system. Such steam demands are considered to be sink elements

and are added to the Site Sink Profile without any temperature

correction.

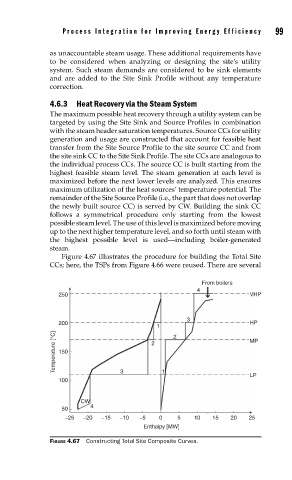

4.6.3 Heat Recovery via the Steam System

The maximum possible heat recovery through a utility system can be

targeted by using the Site Sink and Source Profiles in combination

with the steam header saturation temperatures. Source CCs for utility

generation and usage are constructed that account for feasible heat

transfer from the Site Source Profile to the site source CC and from

the site sink CC to the Site Sink Profile. The site CCs are analogous to

the individual process CCs. The source CC is built starting from the

highest feasible steam level. The steam generation at each level is

maximized before the next lower levels are analyzed. This ensures

maximum utilization of the heat sources’ temperature potential. The

remainder of the Site Source Profile (i.e., the part that does not overlap

the newly built source CC) is served by CW. Building the sink CC

follows a symmetrical procedure only starting from the lowest

possible steam level. The use of this level is maximized before moving

up to the next higher temperature level, and so forth until steam with

the highest possible level is used—including boiler-generated

steam.

Figure 4.67 illustrates the procedure for building the Total Site

CCs; here, the TSPs from Figure 4.66 were reused. There are several

From boilers

4

250 VHP

3

200 HP

1 2

Temperature [°C] 150 2 MP

3

1

LP

100

CW

4

50

−25 −20 −15 −10 −5 0 5 10 15 20 25

Enthalpy [MW]

FIGURE 4.67 Constructing Total Site Composite Curves.