Page 120 - Sustainability in the Process Industry Integration and Optimization

P. 120

P r o c e s s I n t e g r a t i o n f o r I m p r ov i n g E n e r g y E f f i c i e n c y 97

Emissions

Emissions

Power

Fuel 1

Fuel 2 Condensing HP Steam

Emissions MP Steam

LP Steam

Fuel 3 Plant A Plant B Plant C

Cooling

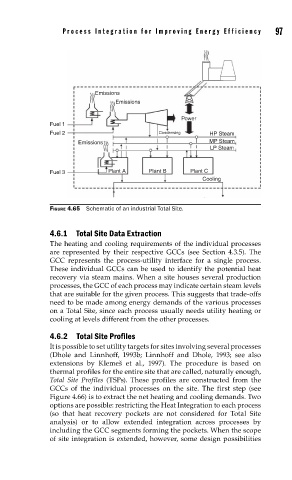

FIGURE 4.65 Schematic of an industrial Total Site.

4.6.1 Total Site Data Extraction

The heating and cooling requirements of the individual processes

are represented by their respective GCCs (see Section 4.3.5). The

GCC represents the process-utility interface for a single process.

These individual GCCs can be used to identify the potential heat

recovery via steam mains. When a site houses several production

processes, the GCC of each process may indicate certain steam levels

that are suitable for the given process. This suggests that trade-offs

need to be made among energy demands of the various processes

on a Total Site, since each process usually needs utility heating or

cooling at levels different from the other processes.

4.6.2 Total Site Profiles

It is possible to set utility targets for sites involving several processes

(Dhole and Linnhoff, 1993b; Linnhoff and Dhole, 1993; see also

extensions by Klemeš et al., 1997). The procedure is based on

thermal profiles for the entire site that are called, naturally enough,

Total Site Profiles (TSPs). These profiles are constructed from the

GCCs of the individual processes on the site. The first step (see

Figure 4.66) is to extract the net heating and cooling demands. Two

options are possible: restricting the Heat Integration to each process

(so that heat recovery pockets are not considered for Total Site

analysis) or to allow extended integration across processes by

including the GCC segments forming the pockets. When the scope

of site integration is extended, however, some design possibilities