Page 123 - Sustainability in the Process Industry Integration and Optimization

P. 123

100 Cha p te r F o u r

steam pressure levels, which are represented by their corresponding

saturation temperatures. The main distribution levels are high-

pressure (HP) steam at a saturation temperature of 200°C , medium-

pressure (MP) steam at 170°C, and LP steam at 115°C. In addition,

very-high-pressure (VHP) steam at 250°C is generated by the steam

boilers, and CW is also available.

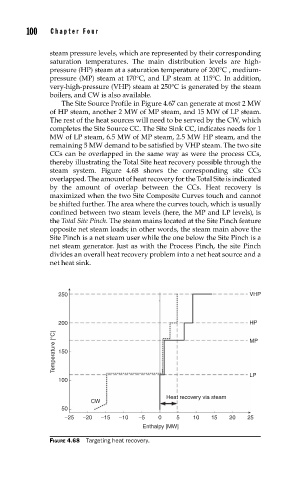

The Site Source Profile in Figure 4.67 can generate at most 2 MW

of HP steam, another 2 MW of MP steam, and 15 MW of LP steam.

The rest of the heat sources will need to be served by the CW, which

completes the Site Source CC. The Site Sink CC, indicates needs for 1

MW of LP steam, 6.5 MW of MP steam, 2.5 MW HP steam, and the

remaining 5 MW demand to be satisfied by VHP steam. The two site

CCs can be overlapped in the same way as were the process CCs,

thereby illustrating the Total Site heat recovery possible through the

steam system. Figure 4.68 shows the corresponding site CCs

overlapped. The amount of heat recovery for the Total Site is indicated

by the amount of overlap between the CCs. Heat recovery is

maximized when the two Site Composite Curves touch and cannot

be shifted further. The area where the curves touch, which is usually

confined between two steam levels (here, the MP and LP levels), is

the Total Site Pinch. The steam mains located at the Site Pinch feature

opposite net steam loads; in other words, the steam main above the

Site Pinch is a net steam user while the one below the Site Pinch is a

net steam generator. Just as with the Process Pinch, the site Pinch

divides an overall heat recovery problem into a net heat source and a

net heat sink.

250 VHP

200 HP

Temperature [°C] 150 MP

LP

100

Heat recovery via steam

CW

50

−25 −20 −15 −10 −5 0 5 10 15 20 25

Enthalpy [MW]

FIGURE 4.68 Targeting heat recovery.