Page 131 - Materials Chemistry, Second Edition

P. 131

Ch003-P373623.qxd 3/22/07 5:29 PM Page 110

Sustainable Industrial Design and Waste Management

110

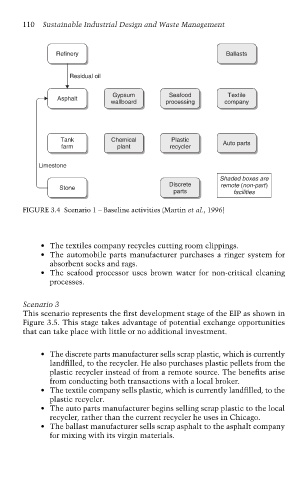

Refinery Ballasts

Residual oil

Gypsum Seafood Textile

Asphalt

wallboard processing company

Tank Chemical Plastic Auto parts

farm plant recycler

Limestone

Shaded boxes are

Discrete remote (non-part)

Stone

parts facilities

FIGURE 3.4 Scenario 1 – Baseline activities (Martin et al., 1996)

• The textiles company recycles cutting room clippings.

• The automobile parts manufacturer purchases a ringer system for

absorbent socks and rags.

• The seafood processor uses brown water for non-critical cleaning

processes.

Scenario 3

This scenario represents the first development stage of the EIP as shown in

Figure 3.5. This stage takes advantage of potential exchange opportunities

that can take place with little or no additional investment.

• The discrete parts manufacturer sells scrap plastic, which is currently

landfilled, to the recycler. He also purchases plastic pellets from the

plastic recycler instead of from a remote source. The benefits arise

from conducting both transactions with a local broker.

• The textile company sells plastic, which is currently landfilled, to the

plastic recycler.

• The auto parts manufacturer begins selling scrap plastic to the local

recycler, rather than the current recycler he uses in Chicago.

• The ballast manufacturer sells scrap asphalt to the asphalt company

for mixing with its virgin materials.