Page 133 - Materials Chemistry, Second Edition

P. 133

Ch003-P373623.qxd 3/22/07 5:29 PM Page 112

Sustainable Industrial Design and Waste Management

112

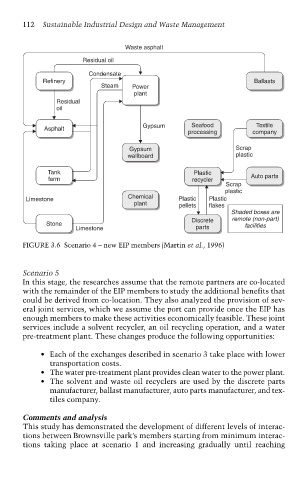

Waste asphalt

Residual oil

Condensate

Refinery Ballasts

Steam Power

plant

Residual

oil

Gypsum Seafood Textile

Asphalt

processing company

Gypsum Scrap

wallboard plastic

Tank Plastic

farm recycler Auto parts

Scrap

plastic

Chemical

Limestone Plastic Plastic

plant pellets flakes

Shaded boxes are

Discrete remote (non-part)

Stone facilities

Limestone parts

FIGURE 3.6 Scenario 4 – new EIP members (Martin et al., 1996)

Scenario 5

In this stage, the researches assume that the remote partners are co-located

with the remainder of the EIP members to study the additional benefits that

could be derived from co-location. They also analyzed the provision of sev-

eral joint services, which we assume the port can provide once the EIP has

enough members to make these activities economically feasible. These joint

services include a solvent recycler, an oil recycling operation, and a water

pre-treatment plant. These changes produce the following opportunities:

• Each of the exchanges described in scenario 3 take place with lower

transportation costs.

• The water pre-treatment plant provides clean water to the power plant.

• The solvent and waste oil recyclers are used by the discrete parts

manufacturer, ballast manufacturer, auto parts manufacturer, and tex-

tiles company.

Comments and analysis

This study has demonstrated the development of different levels of interac-

tions between Brownsville park’s members starting from minimum interac-

tions taking place at scenario 1 and increasing gradually until reaching