Page 117 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 117

Packaged CHP Systems 95

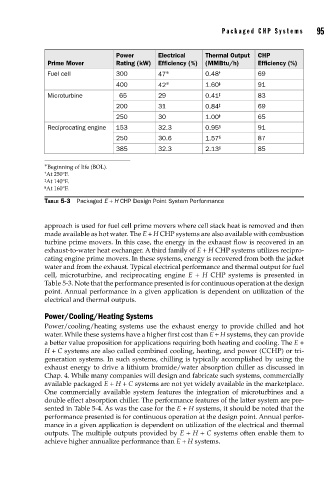

Power Electrical Thermal Output CHP

Prime Mover Rating (kW) Efficiency (%) (MMBtu/h) Efficiency (%)

Fuel cell 300 47 ∗ 0.48 † 69

400 42 ∗ 1.60 ‡ 91

Microturbine 65 29 0.41 ‡ 83

200 31 0.84 ‡ 69

250 30 1.00 ‡ 65

Reciprocating engine 153 32.3 0.95 § 91

250 30.6 1.57 § 87

385 32.3 2.13 § 85

∗ Beginning of life (BOL).

† At 250°F.

‡ At 140°F.

§ At 160°F.

TABLE 5-3 Packaged E + H CHP Design Point System Performance

approach is used for fuel cell prime movers where cell stack heat is removed and then

made available as hot water. The E + H CHP systems are also available with combustion

turbine prime movers. In this case, the energy in the exhaust flow is recovered in an

exhaust-to-water heat exchanger. A third family of E + H CHP systems utilizes recipro-

cating engine prime movers. In these systems, energy is recovered from both the jacket

water and from the exhaust. Typical electrical performance and thermal output for fuel

cell, microturbine, and reciprocating engine E + H CHP systems is presented in

Table 5-3. Note that the performance presented is for continuous operation at the design

point. Annual performance in a given application is dependent on utilization of the

electrical and thermal outputs.

Power/Cooling/Heating Systems

Power/cooling/heating systems use the exhaust energy to provide chilled and hot

water. While these systems have a higher first cost than E + H systems, they can provide

a better value proposition for applications requiring both heating and cooling. The E +

H + C systems are also called combined cooling, heating, and power (CCHP) or tri-

generation systems. In such systems, chilling is typically accomplished by using the

exhaust energy to drive a lithium bromide/water absorption chiller as discussed in

Chap. 4. While many companies will design and fabricate such systems, commercially

available packaged E + H + C systems are not yet widely available in the marketplace.

One commercially available system features the integration of microturbines and a

double effect absorption chiller. The performance features of the latter system are pre-

sented in Table 5-4. As was the case for the E + H systems, it should be noted that the

performance presented is for continuous operation at the design point. Annual perfor-

mance in a given application is dependent on utilization of the electrical and thermal

outputs. The multiple outputs provided by E + H + C systems often enable them to

achieve higher annualize performance than E + H systems.