Page 328 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 328

Sustaining Operational Ef ficiency of a CHP System 301

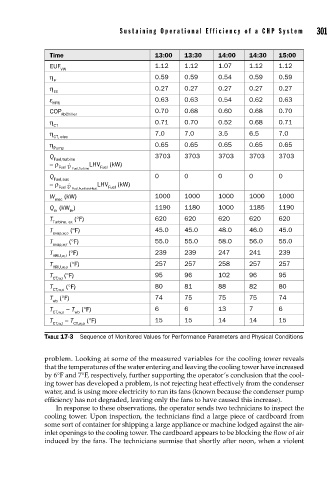

Time 13:00 13:30 14:00 14:30 15:00

EUF 1.12 1.12 1.07 1.12 1.12

VW

η 0.59 0.59 0.54 0.59 0.59

F

η 0.27 0.27 0.27 0.27 0.27

EE

ε 0.63 0.63 0.54 0.62 0.63

HRU

COP 0.70 0.68 0.60 0.68 0.70

AbChiller

η 0.71 0.70 0.52 0.68 0.71

CT

η 7.0 7.0 3.5 6.5 7.0

CT, elec

η 0.65 0.65 0.65 0.65 0.65

Pump

Q Fuel,turbine 3703 3703 3703 3703 3703

= ρ LHV (kW)

Fuel v Fuel,Turbine Fuel

Q Fuel,aux 0 0 0 0 0

= ρ LHV (kW)

Fuel v Fuel,AuxiliaryHeat Fuel

W (kW) 1000 1000 1000 1000 1000

elec

Q (kW ) 1190 1180 1000 1185 1190

th th

T (°F) 620 620 620 620 620

Turbine, ex

T (°F) 45.0 45.0 48.0 46.0 45.0

evap,w,o

T (°F) 55.0 55.0 58.0 56.0 55.0

evap,w,i

T (°F) 239 239 247 241 239

HRU,w,i

T (°F) 257 257 258 257 257

HRU,w,o

T (°F) 95 96 102 96 95

CT,w,i

T (°F) 80 81 88 82 80

CT,w,o

T (°F) 74 75 75 75 74

wb

T − T (°F) 6 6 13 7 6

CT,w,o wb

T − T (°F) 15 15 14 14 15

CT,w,i CT,w,o

TABLE 17-3 Sequence of Monitored Values for Performance Parameters and Physical Conditions

problem. Looking at some of the measured variables for the cooling tower reveals

that the temperatures of the water entering and leaving the cooling tower have increased

by 6°F and 7°F, respectively, further supporting the operator’s conclusion that the cool-

ing tower has developed a problem, is not rejecting heat effectively from the condenser

water, and is using more electricity to run its fans (known because the condenser pump

efficiency has not degraded, leaving only the fans to have caused this increase).

In response to these observations, the operator sends two technicians to inspect the

cooling tower. Upon inspection, the technicians find a large piece of cardboard from

some sort of container for shipping a large appliance or machine lodged against the air-

inlet openings to the cooling tower. The cardboard appears to be blocking the flow of air

induced by the fans. The technicians surmise that shortly after noon, when a violent