Page 357 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 357

330 Ca s e S t u d y 1

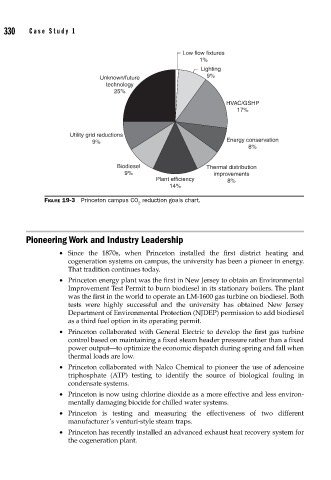

Low flow fixtures

1%

Lighting

Unknown/future 9%

technology

25%

HVAC/GSHP

17%

Utility grid reductions

9% Energy conservation

8%

Biodiesel Thermal distribution

9% improvements

Plant efficiency 8%

14%

FIGURE 19-3 Princeton campus CO reduction goals chart.

2

Pioneering Work and Industry Leadership

• Since the 1870s, when Princeton installed the first district heating and

cogeneration systems on campus, the university has been a pioneer in energy.

That tradition continues today.

• Princeton energy plant was the first in New Jersey to obtain an Environmental

Improvement Test Permit to burn biodiesel in its stationary boilers. The plant

was the first in the world to operate an LM-1600 gas turbine on biodiesel. Both

tests were highly successful and the university has obtained New Jersey

Department of Environmental Protection (NJDEP) permission to add biodiesel

as a third fuel option in its operating permit.

• Princeton collaborated with General Electric to develop the first gas turbine

control based on maintaining a fixed steam header pressure rather than a fixed

power output—to optimize the economic dispatch during spring and fall when

thermal loads are low.

• Princeton collaborated with Nalco Chemical to pioneer the use of adenosine

triphosphate (ATP) testing to identify the source of biological fouling in

condensate systems.

• Princeton is now using chlorine dioxide as a more effective and less environ-

mentally damaging biocide for chilled water systems.

• Princeton is testing and measuring the effectiveness of two different

manufacturer’s venturi-style steam traps.

• Princeton has recently installed an advanced exhaust heat recovery system for

the cogeneration plant.