Page 229 -

P. 229

196 Part 3 • the analysis Process

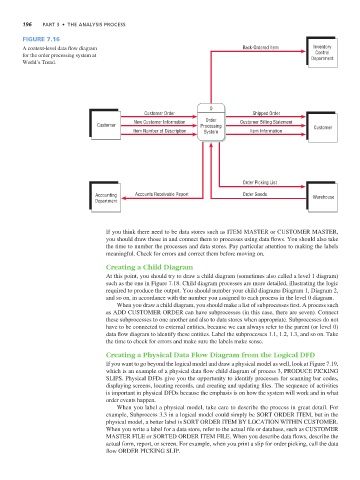

Figure 7.16

y

A context-level data flow diagram Back-Ordered Item Inventory

Control

for the order processing system at Department

World’s Trend.

0

Customer Order Shipped Order

New Customer Information Order Customer Billing Statement

Customer Processing Customer

Item Number of Description System Item Information

Order Picking List

Accounting Accounts Receivable Report Order Goods Warehouse

Department

If you think there need to be data stores such as ITEM MASTER or CUSTOMER MASTER,

you should draw those in and connect them to processes using data flows. You should also take

the time to number the processes and data stores. Pay particular attention to making the labels

meaningful. Check for errors and correct them before moving on.

Creating a Child Diagram

At this point, you should try to draw a child diagram (sometimes also called a level 1 diagram)

such as the one in Figure 7.18. Child diagram processes are more detailed, illustrating the logic

required to produce the output. You should number your child diagrams Diagram 1, Diagram 2,

and so on, in accordance with the number you assigned to each process in the level 0 diagram.

When you draw a child diagram, you should make a list of subprocesses first. A process such

as ADD CUSTOMER ORDER can have subprocesses (in this case, there are seven). Connect

these subprocesses to one another and also to data stores when appropriate. Subprocesses do not

have to be connected to external entities, because we can always refer to the parent (or level 0)

data flow diagram to identify these entities. Label the subprocesses 1.1, 1.2, 1.3, and so on. Take

the time to check for errors and make sure the labels make sense.

Creating a Physical Data Flow Diagram from the Logical DFD

If you want to go beyond the logical model and draw a physical model as well, look at Figure 7.19,

which is an example of a physical data flow child diagram of process 3, PRODUCE PICKING

SLIPS. Physical DFDs give you the opportunity to identify processes for scanning bar codes,

displaying screens, locating records, and creating and updating files. The sequence of activities

is important in physical DFDs because the emphasis is on how the system will work and in what

order events happen.

When you label a physical model, take care to describe the process in great detail. For

example, Subprocess 3.3 in a logical model could simply be SORT ORDER ITEM, but in the

physical model, a better label is SORT ORDER ITEM BY LOCATION WITHIN CUSTOMER.

When you write a label for a data store, refer to the actual file or database, such as CUSTOMER

MASTER FILE or SORTED ORDER ITEM FILE. When you describe data flows, describe the

actual form, report, or screen. For example, when you print a slip for order picking, call the data

flow ORDER PICKING SLIP.