Page 213 - TPM A Route to World-Class Performance

P. 213

190 TPM-A Route to Would-Class Performance

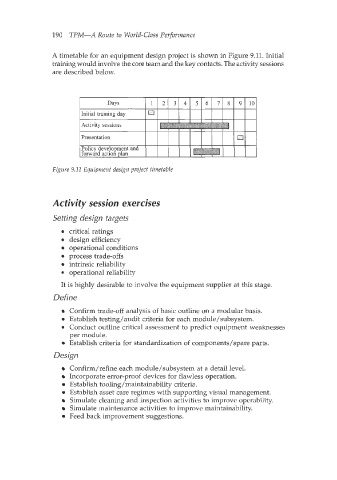

A timetable for an equipment design project is shown in Figure 9.11. Initial

training would involve the core team and the key contacts. The activity sessions

are described below.

Figure 9.11 Equipment design project timetable

A cfivify session exercises

Setting design targets

critical ratings

design efficiency

operational conditions

process trade-offs

intrinsic reliability

0 operational reliability

It is highly desirable to involve the equipment supplier at this stage.

Define

Confirm trade-off analysis of basic outline on a modular basis.

Establish testing/audit criteria for each module/subsystem.

0 Conduct outline critical assessment to predict equipment weaknesses

per module.

Establish criteria for standardization of components/spare parts.

Design

Confirm/refine each module/subsystem at a detail level.

Incorporate error-proof devices for flawless operation.

Establish tooling/maintainability criteria.

Establish asset care regimes with supporting visual management.

Simulate cleaning and inspection activities to improve operability.

Simulate maintenance activities to improve maintainability.

Feed back improvement suggestions.