Page 91 - TPM A Route to World-Class Performance

P. 91

72 TPM-A Route to World-Class Performance

Autonomous inspection i Product quality

Cheral inspection 1 Knows the function

and structure of

Cleaning and lubrication equipment

, I] 4 standards i

1

procedures of equipment

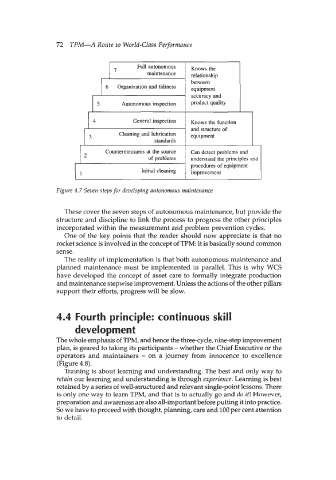

Figure 4.7 Seven steps for developing autonomous maintenance

These cover the seven steps of autonomous maintenance, but provide the

structure and discipline to link the process to progress the other principles

incorporated within the measurement and problem prevention cycles.

One of the key points that the reader should now appreciate is that no

rocket science is involved in the concept of TPM: it is basically sound common

sense.

The reality of implementation is that both autonomous maintenance and

planned maintenance must be implemented in parallel. This is why WCS

have developed the concept of asset care to formally integrate production

and maintenance stepwise improvement. Unless the actions of the other pillars

support their efforts, progress will be slow.

4.4 Fourth principle: continuous skill

development

The whole emphasis of TPM, and hence the three-cycle, nine-step improvement

plan, is geared to taking its participants - whether the Chief Executive or the

operators and maintainers - on a journey from innocence to excellence

(Figure 4.8).

Training is about learning and understanding. The best and only way to

retain our learning and understanding is through experience. Learning is best

retained by a series of well-structured and relevant single-point lessons. There

is only one way to learn TPM, and that is to actually go and do if! However,

preparation and awareness are also all-important before putting it into practice.

So we have to proceed with thought, planning, care and 100 per cent attention

to detail.