Page 94 - TPM A Route to World-Class Performance

P. 94

Techniques to deliver fhe TPM principles 75

The infrastructure of core TPM teams supported by key contacts (see Figure

3.13) reflects the importance of TPM (D) both in retrofit on existing assets and

for the next generation of equipment. Table 4.1 shows that this vital pillar is

also focused through the measurement and problem prevention cycles of the

nine-step TPM improvement plan. Chapter 9 is devoted to the subject of

TPM for equipment designers, specifiers and planners.

4.6 Company-wide TPM

As equipment losses are brought more under control, management attention

can be directed towards other issues in the value stream/supply chain.

The progression of classic TPM into company-wide TPM recognized the

need to define more closely the changing roles of maintainers and managers

as they evolve from looking inward to becoming customer-focused.

The importance of safety is also given recognition as well as TPM in the

off ice environment. The number of pillar champions under company-wide

TPM has increased from five to eight.

The classic five principles are a good starting point for implementing top-

down roles. These correspond closely to key management roles (Table 4.2).

Management’s role in TPM is to create an environment which pulls through

continuous improvement bottom-up rather than pushing initiatives top-down.

A good way of explaining the five pillar champion roles is by linking the

pillar champion to the five questions set out in Chapter 3.

Champion Question

OEE Why don’t we know the consequences of failure (both obvious

and hidden)?

OAC Why does this part of the process not work as it is meant to?

MAC Why can’t we improve the reliability?

CSD Why don’t we have the skills to set optimal conditions?

EEM Why can’t we maintain and improve our technology to maintain

optimal conditions for longer?

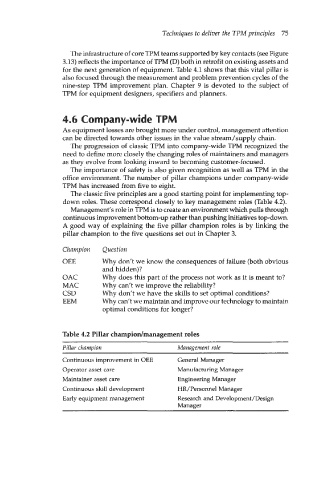

Table 4.2 Pillar championlmanagement roles

Pillar champion Management role

Continuous improvement in OEE General Manager

Operator asset care Manufacturing Manager

Maintainer asset care Engineering Manager

Continuous skill development HR/Personnel Manager

Early equipment management Research and Development/Design

Manager