Page 54 - TPM A Route to World-Class Performance

P. 54

The top-down and bottom-up realities of TPM 35

PERFORMANCE ENHANCEMENT THROUGH

CONTINUOUS IMPROVEMENT

performance

ManagementLevei 1 measurement

Supervisory

Leve Availability x Production rate x Quality rdte \

/

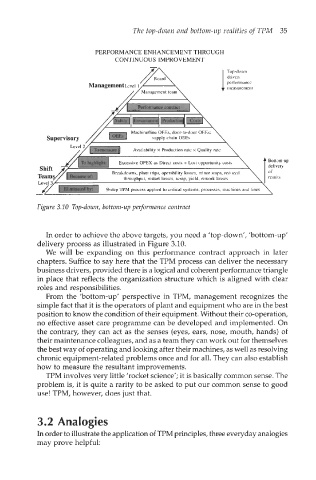

Figure 3.10 Top-down, bottom-up performance contract

In order to achieve the above targets, you need a ’top-down’, ‘bottom-up’

delivery process as illustrated in Figure 3.10.

We will be expanding on this performance contract approach in later

chapters. Suffice to say here that the TPM process can deliver the necessary

business drivers, provided there is a logical and coherent performance triangle

in place that reflects the organization structure which is aligned with clear

roles and responsibilities.

From the ’bottom-up’ perspective in TPM, management recognizes the

simple fact that it is the operators of plant and equipment who are in the best

position to know the condition of their equipment. Without their co-operation,

no effective asset care programme can be developed and implemented. On

the contrary, they can act as the senses (eyes, ears, nose, mouth, hands) of

their maintenance colleagues, and as a team they can work out for themselves

the best way of operating and looking after their machines, as well as resolving

chronic equipment-related problems once and for all. They can also establish

how to measure the resultant improvements.

TPM involves very little ’rocket science’; it is basically common sense. The

problem is, it is quite a rarity to be asked to put our common sense to good

use! TPM, however, does just that.

3.2 Analogies

In order to illustrate the application of TPM principles, three everyday analogies

may prove helpful: