Page 159 - The Jet Engine

P. 159

Ice protection

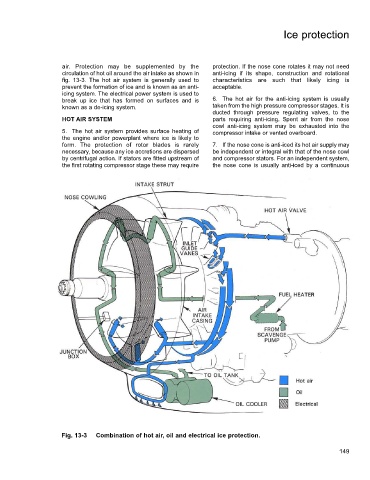

air. Protection may be supplemented by the protection. If the nose cone rotates it may not need

circulation of hot oil around the air intake as shown in anti-icing if its shape, construction and rotational

fig. 13-3. The hot air system is generally used to characteristics are such that likely icing is

prevent the formation of ice and is known as an anti- acceptable.

icing system. The electrical power system is used to

break up ice that has formed on surfaces and is 6. The hot air for the anti-icing system is usually

known as a de-icing system. taken from the high pressure compressor stages. It is

ducted through pressure regulating valves, to the

HOT AIR SYSTEM parts requiring anti-icing. Spent air from the nose

cowl anti-icing system may be exhausted into the

5. The hot air system provides surface heating of compressor intake or vented overboard.

the engine and/or powerplant where ice is likely to

form. The protection of rotor blades is rarely 7. If the nose cone is anti-iced its hot air supply may

necessary, because any ice accretions are dispersed be independent or integral with that of the nose cowl

by centrifugal action. If stators are fitted upstream of and compressor stators. For an independent system,

the first rotating compressor stage these may require the nose cone is usually anti-iced by a continuous

Fig. 13-3 Combination of hot air, oil and electrical ice protection.

149