Page 164 - The Jet Engine

P. 164

Fire protection

However, if ignition should occur, this high velocity air FIRE DETECTION

stream may have to be shut off, otherwise it would

increase the flame intensity and reduce the effective- 11. The rapid detection of a fire is essential to

ness of the extinguishing system by rapid dispersal minimize the fire period before engine shut-down drill

of the extinguishant. and release of extinguishant is effected. It is also

extremely important that a fire detection system will

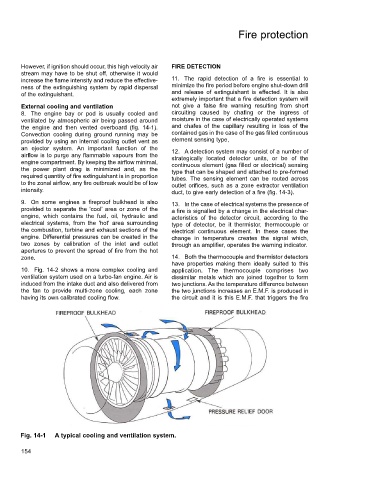

External cooling and ventilation not give a false fire warning resulting from short

8. The engine bay or pod is usually cooled and circuiting caused by chafing or the ingress of

ventilated by atmospheric air being passed around moisture in the case of electrically operated systems

the engine and then vented overboard (fig. 14-1). and chafes of the capillary resulting in loss of the

Convection cooling during ground running may be contained gas in the case of the gas filled continuous

provided by using an internal cooling outlet vent as element sensing type,

an ejector system. An important function of the 12. A detection system may consist of a number of

airflow is to purge any flammable vapours from the strategically located detector units, or be of the

engine compartment. By keeping the airflow minimal, continuous element (gas filled or electrical) sensing

the power plant drag is minimized and, as the type that can be shaped and attached to pre-formed

required quantity of fire extinguishant is in proportion tubes. The sensing element can be routed across

to the zonal airflow, any fire outbreak would be of low outlet orifices, such as a zone extractor ventilation

intensity. duct, to give early detection of a fire (fig. 14-3).

9. On some engines a fireproof bulkhead is also 13. In the case of electrical systems the presence of

provided to separate the 'cool' area or zone of the a fire is signalled by a change in the electrical char-

engine, which contains the fuel, oil, hydraulic and acteristics of the detector circuit, according to the

electrical systems, from the 'hot' area surrounding type of detector, be it thermistor, thermocouple or

the combustion, turbine and exhaust sections of the electrical continuous element. In these cases the

engine. Differential pressures can be created in the change in temperature creates the signal which,

two zones by calibration of the inlet and outlet through an amplifier, operates the warning indicator.

apertures to prevent the spread of fire from the hot

zone. 14. Both the thermocouple and thermistor detectors

have properties making them ideally suited to this

10. Fig. 14-2 shows a more complex cooling and application. The thermocouple comprises two

ventilation system used on a turbo-fan engine. Air is dissimilar metals which are joined together to form

induced from the intake duct and also delivered from two junctions. As the temperature difference between

the fan to provide multi-zone cooling, each zone the two junctions increases an E.M.F. is produced in

having its own calibrated cooling flow. the circuit and it is this E.M.F. that triggers the fire

Fig. 14-1 A typical cooling and ventilation system.

154