Page 29 - The Jet Engine

P. 29

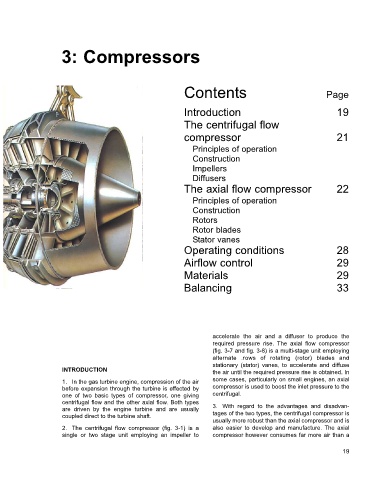

3: Compressors

Contents Page

Introduction 19

The centrifugal flow

compressor 21

Principles of operation

Construction

Impellers

Diffusers

The axial flow compressor 22

Principles of operation

Construction

Rotors

Rotor blades

Stator vanes

Operating conditions 28

Airflow control 29

Materials 29

Balancing 33

accelerate the air and a diffuser to produce the

required pressure rise. The axial flow compressor

(fig. 3-7 and fig. 3-8) is a multi-stage unit employing

alternate .rows of rotating (rotor) blades and

stationary (stator) vanes, to accelerate and diffuse

INTRODUCTION the air until the required pressure rise is obtained. In

1. In the gas turbine engine, compression of the air some cases, particularly on small engines, an axial

before expansion through the turbine is effected by compressor is used to boost the inlet pressure to the

one of two basic types of compressor, one giving centrifugal.

centrifugal flow and the other axial flow. Both types

are driven by the engine turbine and are usually 3. With regard to the advantages and disadvan-

coupled direct to the turbine shaft. tages of the two types, the centrifugal compressor is

usually more robust than the axial compressor and is

2. The centrifugal flow compressor (fig. 3-1) is a also easier to develop and manufacture. The axial

single or two stage unit employing an impeller to compressor however consumes far more air than a

19