Page 31 - The Jet Engine

P. 31

Compressors

THE CENTRIFUGAL FLOW COMPRESSOR per sec. By operating at such high tip speeds the air

velocity from the impeller is increased so that greater

5. Centrifugal flow compressors have a single or energy is available for conversion to pressure.

double-sided impeller and occasionally a two-stage,

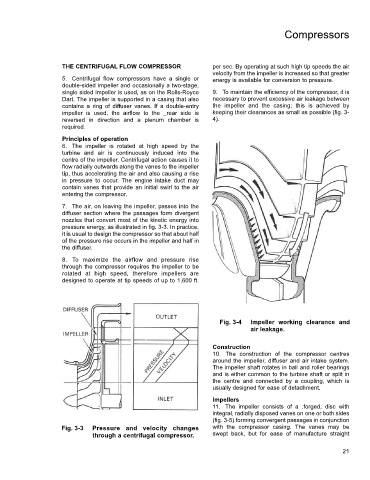

single sided impeller is used, as on the Rolls-Royce 9. To maintain the efficiency of the compressor, it is

Dart. The impeller is supported in a casing that also necessary to prevent excessive air leakage between

contains a ring of diffuser vanes. If a double-entry the impeller and the casing; this is achieved by

impeller is used, the airflow to the _rear side is keeping their clearances as small as possible (fig. 3-

reversed in direction and a plenum chamber is 4).

required.

Principles of operation

6. The impeller is rotated at high speed by the

turbine and air is continuously induced into the

centre of the impeller. Centrifugal action causes it to

flow radially outwards along the vanes to the impeller

tip, thus accelerating the air and also causing a rise

in pressure to occur. The engine intake duct may

contain vanes that provide an initial swirl to the air

entering the compressor.

7. The air, on leaving the impeller, passes into the

diffuser section where the passages form divergent

nozzles that convert most of the kinetic energy into

pressure energy, as illustrated in fig. 3-3. In practice,

it is usual to design the compressor so that about half

of the pressure rise occurs in the impeller and half in

the diffuser.

8. To maximize the airflow and pressure rise

through the compressor requires the impeller to be

rotated at high speed, therefore impellers are

designed to operate at tip speeds of up to 1,600 ft.

Fig. 3-4 Impeller working clearance and

air leakage.

Construction

10. The construction of the compressor centres

around the impeller, diffuser and air intake system.

The impeller shaft rotates in ball and roller bearings

and is either common to the turbine shaft or split in

the centre and connected by a coupling, which is

usually designed for ease of detachment.

Impellers

11. The impeller consists of a .forged, disc with

integral, radially disposed vanes on one or both sides

(fig. 3-5) forming convergent passages in conjunction

Fig. 3-3 Pressure and velocity changes with the compressor casing. The vanes may be

through a centrifugal compressor. swept back, but for ease of manufacture straight

21