Page 118 -

P. 118

Stuffing Box Sealing

STUFFING

BOX GLAND

ROTARY UNIT

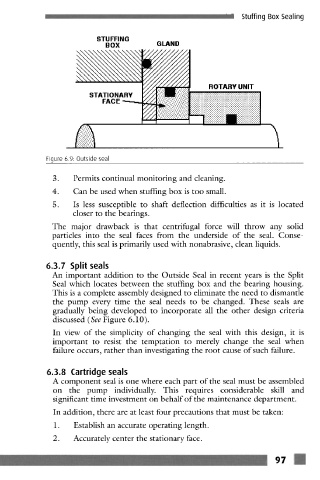

Figure 6.9: Outside seal

3. Permits continual monitoring and cleaning.

4. Can be used when stuffing box is too small.

5. Is less susceptible to shaft deflection difficulties as it is located

closer to the beatings.

The major drawback is that centrifugal force will throw any solid

particles into the seal faces from the underside of the seal. Conse-

quently, this seal is primarily used with nonabrasive, clean liquids.

6.3.7 Split seals

An important addition to the Outside Seal in recent years is the Split

Seal which locates between the stuffing box and the beating housing.

This is a complete assembly designed to eliminate the need to dismantle

the pump every time the seal needs to be changed. These seals are

gradually being developed to incorporate all the other design criteria

discussed ( See Figure 6.10).

In view of the simplicity of changing the seal with this design, it is

important to resist the temptation to merely change the seal when

failure occurs, rather than investigating the root cause of such failure.

6.3.8 Cartridge seals

A component seal is one where each part of the seal must be assembled

on the pump individually. This requires considerable skill and

significant time investment on behalf of the maintenance department.

In addition, there are at least four precautions that must be taken:

Establish an accurate operating length.

~

Accurately center the stationary face.

.

97 m