Page 121 -

P. 121

The Practical Pumping Handbook

There are three distinctive arrangements of double seals, all of which

require the use of a Barrier Fluid System to maintain a liquid or gas

barrier between the two sets of seal faces.

A commonly used low cost double seal arrangement is referred to as the

Back to Back Seal. It positions the rotating faces in opposite directions

and should always use a Barrier Fluid pressurized to approximately 20

p.s.i, above the stuffing box pressure. This ensures that the inner seal is

lubricated at all times by the Barrier Fluid, and also contributes to the

closing force on the seal faces.

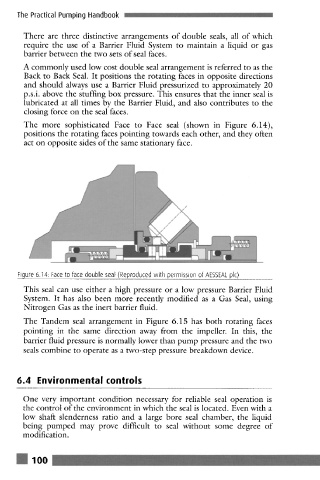

The more sophisticated Face to Face seal (shown in Figure 6.14),

positions the rotating faces pointing towards each other, and they often

act on opposite sides of the same stationary face.

Figure 6.14: Face to face double seal (Reproduced with permission of AESSEAL plc)

This seal can use either a high pressure or a low pressure Barrier Fluid

System. It has also been more recently modified as a Gas Seal, using

Nitrogen Gas as the inert barrier fluid.

The Tandem seal arrangement in Figure 6.15 has both rotating faces

pointing in the same direction away from the impeller. In this, the

barrier fluid pressure is normally lower than pump pressure and the two

seals combine to operate as a two-step pressure breakdown device.

6.4 Environmental controls

One very important condition necessary for reliable seal operation is

the control of the environment in which the seal is located. Even with a

low shaft slenderness ratio and a large bore seal chamber, the liquid

being pumped may prove difficult to seal without some degree of

modification.

100 ; ~ == ~~