Page 124 - The Toyota Way Fieldbook

P. 124

Chapter 5. Create Connected Process Flow 101

Schedule

1 PC 1 PC

Model 2

Model 1 Operation Operation 1 Operation

Model 2 A B C

Model 3 3 2 2

In Process In Process In Process

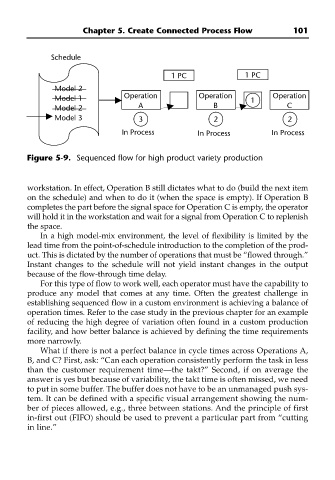

Figure 5-9. Sequenced flow for high product variety production

workstation. In effect, Operation B still dictates what to do (build the next item

on the schedule) and when to do it (when the space is empty). If Operation B

completes the part before the signal space for Operation C is empty, the operator

will hold it in the workstation and wait for a signal from Operation C to replenish

the space.

In a high model-mix environment, the level of flexibility is limited by the

lead time from the point-of-schedule introduction to the completion of the prod-

uct. This is dictated by the number of operations that must be “flowed through.”

Instant changes to the schedule will not yield instant changes in the output

because of the flow-through time delay.

For this type of flow to work well, each operator must have the capability to

produce any model that comes at any time. Often the greatest challenge in

establishing sequenced flow in a custom environment is achieving a balance of

operation times. Refer to the case study in the previous chapter for an example

of reducing the high degree of variation often found in a custom production

facility, and how better balance is achieved by defining the time requirements

more narrowly.

What if there is not a perfect balance in cycle times across Operations A,

B, and C? First, ask: “Can each operation consistently perform the task in less

than the customer requirement time—the takt?” Second, if on average the

answer is yes but because of variability, the takt time is often missed, we need

to put in some buffer. The buffer does not have to be an unmanaged push sys-

tem. It can be defined with a specific visual arrangement showing the num-

ber of pieces allowed, e.g., three between stations. And the principle of first

in-first out (FIFO) should be used to prevent a particular part from “cutting

in line.”