Page 412 - The Toyota Way Fieldbook

P. 412

Chapter 18. Telling the Story Using an A3 Report 385

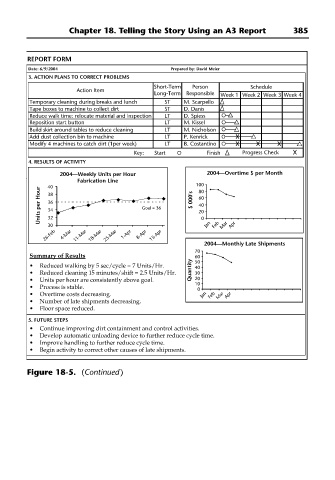

REPORT FORM

Date: 6/9/2004 Prepared by: David Meier

3. ACTION PLANS TO CORRECT PROBLEMS

Short-Term Person Schedule

Action Item

Long-Term Responsible Week 1 Week 2 Week 3 Week 4

Temporary cleaning during breaks and lunch ST M. Scarpello

Tape boxes to machine to collect dirt ST D. Danis

Reduce walk time: relocate material and inspection LT D. Spiess

Reposition start button LT M. Kissel

Build skirt around tables to reduce cleaning LT M. Nicholson

Add dust collection bin to machine LT P. Kenrick

Modify 4 machines to catch dirt (1per week) LT B. Costantino

Key: Start Finish Progress Check

4. RESULTS OF ACTIVITY

2004—Weekly Units per Hour 2004—Overtime $ per Month

Fabrication Line 100

40

Units per Hour 38 Goal = 36 $ 000's 60

80

36

40

34

20

32

30 0 Jan Feb Mar Apr

26-Feb 4-Mar 11-Mar 18-Mar 25-Mar 1-Apr 8-Apr 15-Apr

2004—Monthly Late Shipments

70

Summary of Results 60

• Reduced walking by 5 sec/cycle = 7 Units/Hr. 50

40

• Reduced cleaning 15 minutes/shift = 2.5 Units/Hr. Quantity 30

• Units per hour are consistently above goal. 20

10

• Process is stable. 0

• Overtime costs decreasing. Jan Feb Mar Apr

• Number of late shipments decreasing.

• Floor space reduced.

5. FUTURE STEPS

• Continue improving dirt containment and control activities.

• Develop automatic unloading device to further reduce cycle time.

• Improve handling to further reduce cycle time.

• Begin activity to correct other causes of late shipments.

Figure 18-5. (Continued)