Page 127 - The Tribology Handbook

P. 127

A22 Rolling bearing installation

Seatings (continued)

4 Control the tolerances for out-of-round and conicity errors for the bearing seatings. These errors in total should not

exceed the seating dimensional tolerances selected from Tables 22.3 and 22.4.

5 Adjust the seating limits if necessary, to allow for thermal expansion differences, if special materials other than steel

or cast iron are involved. Allow for the normal fit at the operating temperature, but check that the bearing is neither

excessively tight nor too slack at both extremes of temperature. Steel liners, or liners having an intermediate coefficient

of thermal expansion, will ease this problem. They should be of at least equivalent section to that of the bearing outer

ring.

6 Avoid split housings where possible. Split housings must be accurately dowelled before machining the bearing seatings,

and the dowels arranged to avoid the two halves being fitted more than one way round.

Abutments

1 Ensure that these are sufficiently deep to provide adequate axial support to the bearing faces, particularly where axial

loads are involved.

CLEARANCE

INTERFERENCE

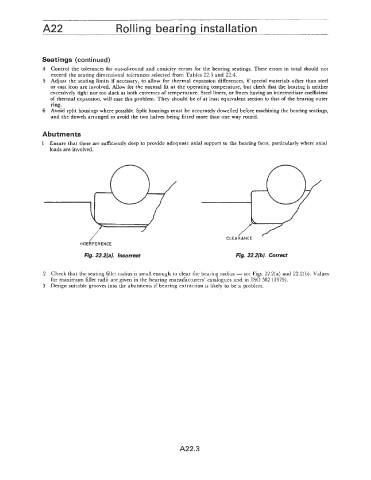

fig. 22.2fa). Incorrect Fig. 22.2M. Correct

2 Check that the seating fillet radius is small enough to clear the bearing radius - see Figs. 22.2(a) and 22.2(b). Values

for maximum fillet radii are given in the bearing manufacturers’ catalogues and in IS0 582 (1979).

3 Design suitable grooves into the abutments if bearing extraction is likely to be a problem.

A22.3