Page 130 - The Tribology Handbook

P. 130

I

Rol i ng bearing i nsta I lation A22

Vertical shaft

1 Use the same principles of mounting as indicated for horizontal shafts.

2 Where possible, locate the shaft at the upper bearing position because greater stability is obtained by supporting a rotating

mass at a )point above its centre of gravity.

3 Take care to ensure correct lubrication and provide adequate means for lubricant retention. Use a No. 3 consistency

grease and minimise the space above the bearings to avoid slumping.

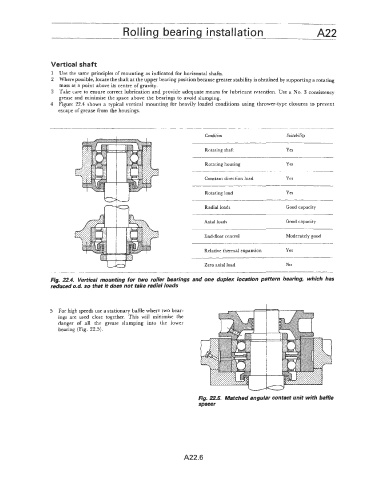

4 Figure 22.4 shows a typical vertical mounting for heavily loaded conditions using thrower-type closures to prevent

escape of grease from the housings.

Condition Suita bi&y

Rotating shaft Yes

Rotating housing Yes

Constant direction load Yes

Rotating load

Radial loads Good capacity

Axial loads Good capacity

End-float control Moderately good

Relative thermal expansion Yes

Zero axial load NO

Fig. 22.4. Vertical mounting for two roller bearings and one duplex location pattern bearing, which has

reduced ad. so that it does not take radial loads

5 For high speeds use a stationary baffle where two bear-

ings are used close together. This will minimise the

danger of all the grease slumping into the lower

bearing (Fig. 22.5).

Fig. 22.5. Matched angular contact unit with baffle

spacer

A22.6