Page 132 - The Tribology Handbook

P. 132

Rolling bearing installation A22

Sealing arrangements

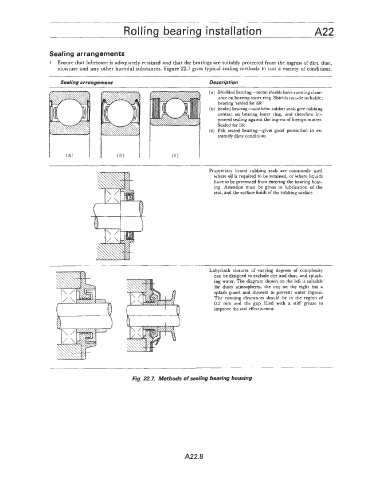

1 Ensure tha.t lubricant is adequately retained and that the bearings are suitably protected from the ingress of dirt, dust,

moisture and any other harmful substances. Figure 22.7 gives typical sealing methods to suit a variety of conditions.

Sealing Wrangement Description

(a) Shielded bearing-metal shields have running ciear-

ance on bearing inner ring. Shields non-detachable;

bearing ‘sealed for life’

(b) Sealed bearing-synthetic rubber seals give rubbing

contact on bearing inner ring, and therefore im-

proved sealing against the ingress of foreign matter.

Sealed for life

(c) Felt sealed bearing-gives good protection in ex-

tremely dirty conditions

Proprietary brand rubbing seals are commonly used

where oil is required to be retained, or where liquids

have to be prevented from entering the bearing hous-

ing. Attention must be given to lubrication of the

seal, and the surface finish of the rubbing surface

Labyrinth closures of varying degrees of complexity

can be designed to exclude dirt and dust, and splash-

ing water. The diagram shown on the left is suitable

for dusty atmospheres, the one on the right has a

splash guard and thrower to prevent water ingress.

The running clearances should be in the region of

0.2 mm and the gap filled with a stiff grease to

improve the seal effectiveness

Fig. 22.7, Methods of sealing bearing housing

A22.8