Page 185 - The Tribology Handbook

P. 185

Flexible couplings B4

COUPLING EFFECTS

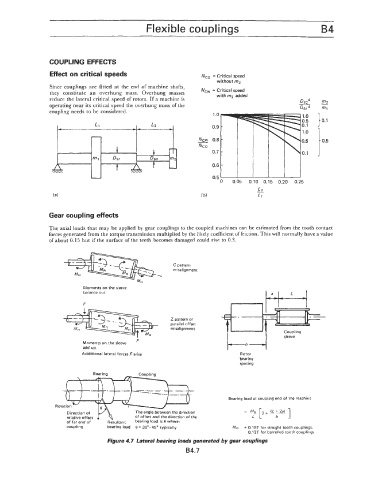

Effect on critical speeds N,, = Critical speed

without m2

Since couplings are fitted at the end of machine shafts,

they constitute an overhung mass. Overhung masses Ncw = Critical speed

withmz added

reduce the lateral critical speed of rotors. If a machine is

operating near its critical speed the overhung mass of the

coupling needs to be considered. 1 .o

0.5 -

0.9

-

0.8

Ncw

Nc 0

0.7

0 0.05 0.10 0.15 0.20 0.25

-

L2

L1

Gear coupling effects

The axial Ioacls that may be applied by gear couplings to the coupled machines can be estimated from the tooth contact

forces generated from the torque transmission multiplied by the likely coefficient of friction. This will normally have a value

of about 0.15 but if the surface of the teeth becomes damaged could rise to 0.3.

C pattern

misalignment

Moments on the sleeve

balance out

F

--

Z pattern or

parallel offset

misalignment

Moments on rhe sleeve

add up.

Additional lateral forces F arise Rotor

bearing

spacing

Bearing load at coupling end of the machine

= - [*+ (L+2ai 1

Direction of The angle between the direction MR

relative offset of offset and the direction of the L b

of far end of ~~~~l~~~~ load is 8 where:

bearing

coupling bearing load 8 = 30"-45' typically MR = 0.16T for straight tooth couplings.

0.12T for barrelled tooth couplings.

Figure 4.7 Lateral bearing loads generated by gear couplings

B4.7