Page 180 - The Tribology Handbook

P. 180

B4 Flexible couplings

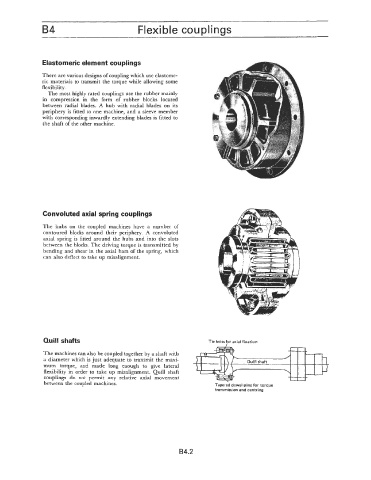

Elastomeric element couplings

There are various designs of coupling which use elastome-

ric materials to transmit the torque while allowing some

flexibility.

The most highly rated couplings use the rubber mainly

in compression in the form of rubber blocks located

between radial blades. A hub with radial blades on its

periphery is fitted to one machine, and a sleeve member

with corresponding inwardly extending blades is fitted to

the shaft of the other machine.

Convoluted axial spring couplings

The hubs on the coupled machines have a number of

contoured blocks around their periphery. A convoluted

axial spring is fitted around the hubs and into the slots

between the blocks. The driving torque is transmitted by

bending and shear in the axial bars of the spring, which

can also deflect to take up misalignment.

Quill shafts lie bolts for axial fixation

The machines can also be coupled together by a shaft with

a diameter which is just adequate to transmit the maxi-

mum torque, and made long enough to give lateral

flexibility in order to take up misalignment. Quill shaft

couplings do not permit any relative axial movement

between the coupled machines. Tapered dowel pins for torque

transmission and centring

B4.2