Page 202 - The Tribology Handbook

P. 202

B8 Brakes

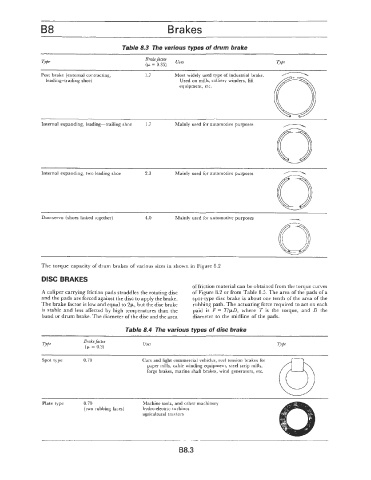

Table 8.3 The various types of drum brake

Brake factor useJ

(k = 0.35)

Post brake (external contracting, 1.7 Most widely used type of industrial brake.

leading-trailing shoe) Used on mills, colliery winders, lift

equipment, etc.

Duo-servo (shoes linked together) 4.0 Mainly used for automotive purposes

The torque capacity of drum brakes of various sizes in shown in Figure 8.2

DISC BRAKES

of friction material can be obtained from the torque curves

A caliper carrying friction pads straddles the rotating disc of Figure 8.2 or from Table 8.5. The area of the pads of a

and the pads are forced against the disc to apply the brake. spot-type disc brake is about one tenth of the area of the

The brake factor is low and equal to 2~, but the disc brake rubbing path. The actuating force required to act on each

is stable and less affected by high temperatures than the paid is F = T/pD, where T is the torque, and D the

band or drum brake. The diameter of the disc and the area diameter to the midline of the pads.

Table 8.4 The various types of disc brake

Brake factor

(p = 0.3) Uses

Spot type 0.70 Cars and light commercial vehicles, reel tension brakes for

paper mills, cable winding equipment, steel strip mills,

forge brakes, marine shaft brakes, wind generators, etc.

Plate type 0.70 Machine tools, and other machinery

(two rubbing faces) hydro-electric turbines

agricultural tractors

B8.3