Page 197 - The Tribology Handbook

P. 197

Friction clutches 87

FITTING OF FRICTION LININGS

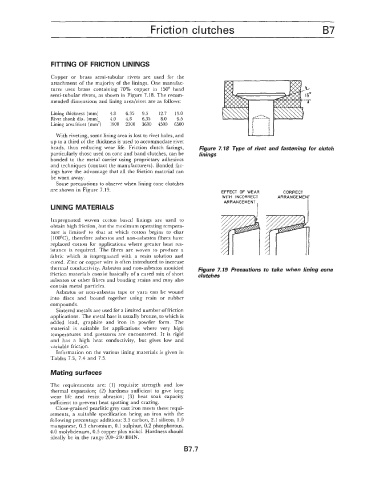

Copper or hlrass semi-tubular rivets are used for the

attachment of the majority of the linings. One manufac-

turer uses brass containing 70% copper in 150" head

semi-tubular rivets, as shown in Figure 7.18. The recom-

mended dimensions and lining area/rivet are as follows:

Lining thickness (mm) 4.8 6.35 9.5 12.7 19.0

Rivet shank dia. (mm) 4.0 4.8 6.35 8.0 9.5

Lining area/rivet (mm2) 1900 2300 3600 4500 6500

With riveting, some lining area is lost to rivet holes, and

up to a third of the thickness is used to accommodate rivet

heads, thus reducing wear life. Friction clutch facings, Figure 7.18 Type of rivet and fastening for clutch

particularly those used on cone and band clutches, can be linings

bonded to the metal carrier using proprietary adhesives

and techniques (contact the manufacturers). Bonded fac-

ings have the advantage that all the friction material can

be worn away.

Some precautions to observe when lining cone clutches

are shown in Figure 7.19. EFFECT OF WEAR CORRECT

WITH INCORRECT ARRANGEMENT

ARRANGEMENT I I

LINING MATERIALS

Impregnated woven cotton based linings are used to

obtain high friction, but the maximum operating tempera-

ture is limite(d to that at which cotton begins to char

(1 OOOC), therefore asbestos and non-asbestos fibres have

replaced cotton for applications where greater heat res-

istance is required. The fibres are woven to produce a

fabric which is impregnated with a resin solution and

cured. Zinc or copper wire is often introduced to increase

thermal conductivity. Asbestos and non-asbestos moulded Figure 7.19 Precautions to take when lining cone

friction materials consist basically of a cured mix of short clutches

asbestos or other fibres and bonding resins and may also

contain metal particles.

Asbestos or non-asbestos tape or yarn can be wound

into discs and bound together using resin or rubber

compounds.

Sintered metals are used for a limited number offriction

applications. The metal base is usually bronze, to which is

added lead, graphite and iron in powder form. The

material is siiitable for applications where very high

temperatures and pressures are encountered. It is rigid

and has a high heat conductivity, but gives low and

variable friction.

Information on the various lining materials is given in

Tables 7.3, 7.4 and 7.5.

Mating surfaces

The requirements are: (1) requisite strength and low

thermal expansion; (2) hardness sufficient to give long

wear life and resist abrasion; (3) heat soak capacity

sufficient to prevent heat spotting and crazing.

Close-grained pearlitic grey cast iron meets these requi-

rements, a suitable specification being an iron with the

following percentage additions: 3.3 carbon, 2.1 silicon, 1 .O

manganese, 0.3 chromium, 0.1 sulphur, 0.2 phosphorous,

4.0 molybdenum, 0.5 copper plus nickel. Hardness should

ideally be in the range 20&230 BHN.

B7.7