Page 196 - The Tribology Handbook

P. 196

B7 Friction clutches

Lining design for oil-immersed clutches

For working in oil, multi-plate clutches are suitable. Oil

acts as a cushion and energy released by heat is carried

away by oil. The main disadvantage is a reduction in

friction, but this can be counteracted by higher operating

pressures. As long as there is an oil film on the plates, the

friction characteristic and engagement torque remain low,

but as soon as the film breaks the engagement torque rises

rapidly and may lead to rapid acceleration. The friction

surface pressure should usually not exceed 1 MN/m2 with

a sliding speed maximum of 20 m/s, steel on steel. With

oil-immersed clutches having steel and sintered plates the

relationship between the static and dynamic coefficient of Figure 7.15 Anti-distortion slot in friction plate

friction is more favourable. Friction surface pressure and

sliding speed may be up to 3 MN/m2 and 30 m/s.

Facing grooves and anti-distortion slots

The most common facing groove is a single- or multi-lead

spiral. This helps to prevent the formation of an oil film,

which, if formed, would lower the coefficient of friction. It

also provides space for the oil to be dispersed during clutch

engagement. Spiral grooves are between 0.6 and 1.5 mm

wide and 0.2-1 mm deep, depending on diameter and face

thickness. The pitch is between 1.5 and 6.0 mm, depend-

ing on the size of the disc.

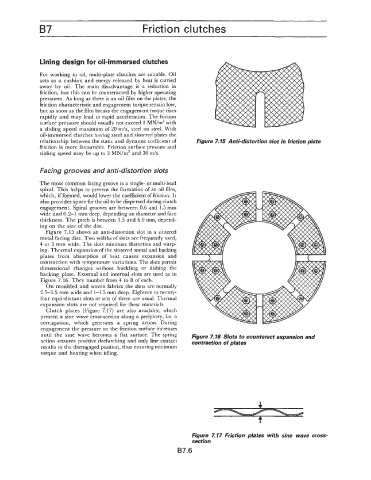

Figure 7.15 shows an anti-distortion slot in a sintered

metal facing disc. Two widths of slots are frequently used,

4 or 5 mm wide. The slots minimise distortion and warp-

ing. Thermal expansion of the sintered metal and backing

plates from absorption of heat causes expansion and

contraction with temperature variations. The slots permit

dimensional changes without buckling or dishing the

backing plate. External and internal slots are used as in

Figure 7.16. They number from 4 to 8 of each.

On moulded and woven fabrics the slots are normally

2.5-3.5 mm wide and 1-1.5 mm deep. Eighteen to twenty-

four equi-distant slots or sets of three are usual. Thermal

expansion slots are not required for these materials.

Clutch plates (Figure 7.17) are also available, which

present a sine wave cross-section along a periphery, i.e. a

corrugation, which generates a spring action. During

engagement the pressure on the friction surface increases

until the sine wave becomes a flat surface. The spring Figure 7.16 Slots to counteract expansion and

action ensures positive declutching and only line contact contraction of plates

results in the disengaged position, thus ensuring minimum

torque and heating when idling.

Figure 7.17 Friction plates with sine wave cross-

section

B7.6