Page 237 - The Tribology Handbook

P. 237

B16 Pistons

DIESEL ENGINE PISTONS

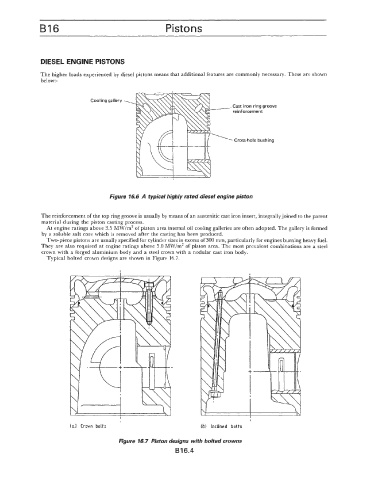

The higher loads experienced by diesel pistons means that additional features are commonly necessary. These are shown

below:-

Cooling gallery

Cast iron ring groove

reinforcement

Cross-hole bushing

Figure 16.6 A typical highly rated diesel engine piston

The reinforcement of the top ring groove is usually by means of an austenitic cast iron insert, integrally joined to the parent

material during the piston casting process.

At engine ratings above 3.5 MW/m2 of piston area internal oil cooling galleries are often adopted. The gallery is formed

by a soluble salt core which is removed after the casting has been produced.

Two-piece pistons are usually specified for cylinder sizes in excess of 300 mm, particularly for engines burning heavy fuel.

They are also required at engine ratings above 5.0 MW/m' of piston area. The most prevalent combinations are a steel

crown with a forged aluminium body and a steel crown with a nodular cast iron body.

Typical bolted crown designs are shown in Figure 16.7.

I

(a1 Crown bolts (b) Inclined botts

Figure 16.7 Piston designs with bolted crowns

B16.4