Page 239 - The Tribology Handbook

P. 239

B16 Pistons

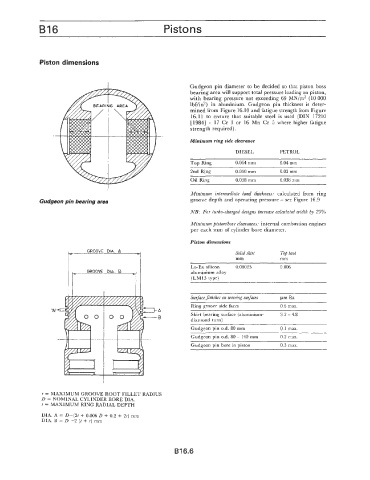

Piston dimensions

Gudgeon pin diameter to be decided so that piston boss

bearing area will support total pressure loading on piston,

with bearing pressure not exceeding 69 MN/m2 (10 000

Ibf/in2) in aluminium. Gudgeon pin thickness is deter-

mined from Figure 16.10 and fatigue strength from Figure

16.11 to ensure that suitable steel is used (DIN 17210

[1984] - 17 Cr 3 or 16 Mn Cr 5 where higher fatigue

strength required).

Minimum ring side clearance

DIESEL PETROL

Top Ring 0.064 mm 0.04 mm

2nd Rins 0.050 mm 0.03 mm

Oil Ring 0.038 mm 0.038 mm

Minimum intermediate land thickness: calculated from ring

Gudgeon pin bearing area groove depth and operating pressure - see Figure 16.9

NB: For turbo-charged designs increase calculated width 29%

Minimum pistodbore clearances: internal combustion engines

per each mm of cylinder bore diameter.

Piston dimensions

Solid skirt Top land

mm mm

Lo-Ex silicon 0.00025 0.006

aluminium alloy

(LM13 type)

Surface finishes on wearing surfaces pm Ra

Ring groove side faces 0.6 max.

Skirt bearing surface (aluminium- 3.2 - 4.8

diamond turn)

Gudgeon pin 0.d. 80 mm 0.1 max.

Gudgeon pin 0.d. 80 - 140 mm 0.2 max.

Gudgeon pin bore in piston 0.3 rnax.

r = MAXIMUM GROOVE ROOT FILLET RADIUS

D = NOMINAL CYLINDER BORE DIA.

t = MAXIMUM RING RADIAL DEPTH

DIA. A = D-(2t + 0.006 D + 0.2 + 2r) mm

DIA. B = D -2 (t + r) mm

B16.6