Page 233 - The Tribology Handbook

P. 233

B15 Damping devices

POINTS TO NOTE IN DAMPER SELECTION AND DESIGN

1. Friction dampers can potentially absorb the most ener-

gy, but are unsuitable for systems subject to steady

oscillations at or near resonance, unless the friction

dampers are large enough to provide a damping force of

at least four times any excitation force.

2. To give satisfactory performance with acceptable wear

rates, the contact pressures in friction pad dampers

should not exceed 250 kN/m2 (34 p.s.i.).

3. With hydraulic dampers, damping factors in the range

0.25 to 0.4 are generally suitable, but at frequency

ratios above r = 2.5 the transmitted forces are higher

than with friction dampers.

4. With viscous hydraulic dampers giving straight line

force/velocity characteristics it is important to specify

the velocity at which the force should be Levelled to a

constant value by a cut-off valve. A valve of adequate

capacity is needed to prevent instantaneous velocity

peaks from bursting the housing or causing damage to

the working valves or the end mountings. The maxi-

mum allowable pressure at cut-off is usually of the

order of 3.5 MN/m2 (500 p.s.i.).

5. If damping devices are likely to be operated near the

resonant frequency of the system, the rigidity of the

rubber pads or mounting bushes need to be checked for

adequate stiffness.

u1

0 +

6

ti

w

0

rr

9

0

f

a

r

a

0

0 DAMPER VELOCITY V, m/5

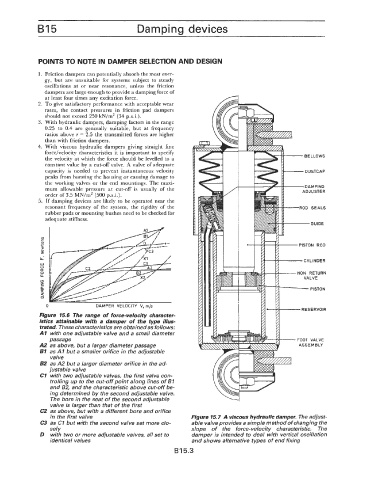

Figure 15.6 The range of force-velocity character-

istics attainable with a damper of the type illus-

trated. These characteristics are obtained as follows:

AI with one adjustable valve and a small diameter

passage

A2 as above, but a larger diameter passage

61 as AI but a smaller orifice in the adjustable

valve

62 as A2 but a larger diameter orifice in the ad-

justable valve

C7 with two adjustable valves, the first valve con-

trolling up to the cut-off point along lines of BI

and B2, and the characteristic above cut-off be-

ing determined by the second adjustable valve.

The bore in the seat of the second adjustable

valve is larger than that of the first

C2 as above, but with a different bore and orifice

in the first valve

C3 as CI but with the second valve set more clo-

sely

D with two or more adjustable valves, all set to

identical values

B 15.3