Page 252 - The Tribology Handbook

P. 252

Selection of seals B19

BASIC SEAL TYPES AND THEIR CHARACTERISTICS

Dynamic seal

Sealing takes place between surfaces in sliding contact or narrowly separated.

Static seal1

Sealing takes place between surfaces which do not move relative to each other.

Pseudo-static seal

Limited relative motion is possible at the sealing surfaces, or the seal itself allows limited motion; e.g. swivel couplings for

pipes, flexible diaphragms.

Exclusion seal

A device to restrict access of dirt, etc., to a system, often used in conjunction with a dynamic seal.

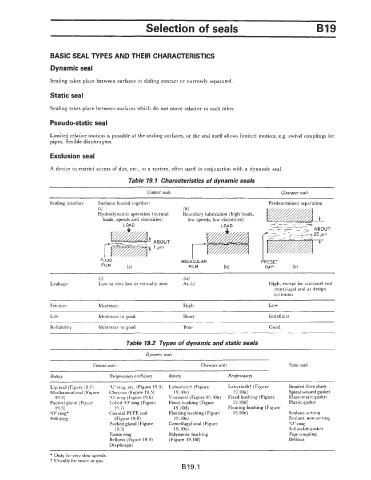

Table 19.1 Characteristics of dynamic seals

Contact seals Clearance seals

Sealing interface Surfaces loaded together: Predetermined separation

(i) (ii)

Hydrodynamic operation (normal Boundary lubrication (high loads,

loads, speeds and viscosities) low speeds, low viscosities)

LOAD

I

FLUID MOLECULAR PRESET

FILM b)

(a) FILM (b) GAP

6) (ii)

Leakage Low to very low or virtually zero As (i) High, except for viscoseal and

centrifugal seal at design

optimum

-

Friction Moderate High Low

Life Moderate to good Short Indefinite

~~ ~~

Reliability Moderate to good Poor Good

Table 19.2 Types of dynamic and static seals

Dynamic seals

Contact seals Clearance seals Static seals

Rotary RecipracatoT oscillatory Rotary Reciprocatory

Lip seal (Figure 19.1) ‘U’ ring, etc. (Figure 19.4) Labyrintht (Figure Labyrinth7 (Figure Bonded fibre sheet

Mechanical seal (Figure Chevron (Figure 19.5) 19.10a) 19.10a) Spiral wound gasket

19.2) ‘0’ ring (Figure 19.6) Viscoseal (Figure 19.10b) Fixed bushing (Figure Elastomeric gasket

Packed gland (Figure Lobed ‘0’ ring (Figure Fixed bushing (Figure 19.10d) Piastic gasket

19.3) 19.7) 19.lOd) Floating bushing (Figure

‘0’ ring* Coaxial PTFE seal Floating bushing (Figure 19. l0e) Sealant, setting

Felt ring (Figure 19.8) 19.10e) Sealant, non-setting

Packed gland (Figure Centrifugal seal (Figure ‘0’ ring

19.3) 19.1Oc) Inflatable gasket

Piston ring Polymeric bushing Pipe coupling

Bellows (Figure 19.9) (Figure 19.101) Bellows

Diaphragm

* Only for very slow speeds.

t Usually for steam or gas.

B19.1