Page 254 - The Tribology Handbook

P. 254

Selection of seals B19

(di (e) (f)

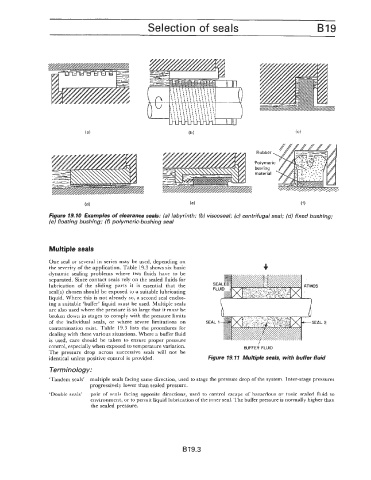

Figure 19.10 Examples of clearance seals: (a) labyrinth; (b) viscoseal; IC) centrifugal seal; (d) fixed bushing;

(e) floating bushing; (f) polymeric-bushing seal

Multiple seals

One seal or several in series may be used, depending on

the severity of the application. Table 19.3 shows six basic

dynamic sealing problems where two fluids have to be

separated. Since contact seals rely on the sealed fluids for

lubrication of the sliding parts it is essential that the

seal(s) chosen should be exposed to a suitable lubricating

liquid. Where thus is not already so, a second seal enclos-

ing a suitable ‘buffer’ liquid must be used Multiple seals

are also used where the pressure is so large that It must be

broken down in stages to comply with the pressure limits

of the individual seals, or where severe limitations on

contamination exist. Table 19.3 lists the procedures for

dealing with these various situations. Where a buffer fluid

is used, care should be taken to ensure proper pressure

control, especially when exposed to temperature variation. BUFFER FLUID

The pressure drop across successive seals will not be

identical unless positive control is provided. Figure 19.11 Multiple seals, with buffer fluid

Terminodolg y:

‘Tandem seals’ multiple seals facing same direction, used to stage the pressure drop of the system. Inter-stage pressures

progressively lower than sealed pressure.

‘Double seals’ pair of seals facing opposite directions, used to control escape of hazardous or toxic sealed fluid to

environment, or to permit liquid lubrication of the inner seal. The buffer pressure is normally higher than

the sealed pressure.

B19.3