Page 64 - The Tribology Handbook

P. 64

High speed bearings and rotor dynamics A10

Shaft lateral vibrations which may occur on machines with high speed rotors

Type of vibration Cause of the vibration Remarks

A vibration at the same frequency as the Unbalance of the rotor Can be reduced by improving the dynamic

shaft rotation which tends to increase balance of the rotor

with speed

A vibration at the same frequency as the The rotor, as supported in the machine, The response of the rotor in terms of

shaft rotation which increases in is laterally flexible and has a natural vibration amplitude will depend on a

amplitude around a particular speed lateral resonance or critical speed at balance between the damping in the

which the vibration amplitude is a system and the degree of rotor unbalance

maximum

A vibration with a frequency ofjust less The rotor is supported in lightly loaded An increase in the specific bearing loading

than half the shaft rotational speed plain journal bearings which can by a reduction in bearing width can help.

which occurs over a range of speeds generate half speed vibration (see Fig. Alternatively bearings with special bore

10.2). The actual frequency is profiles can be used (see Fig. 10.3)

generally just less than half shaft speed

due to damping

A vibration with a frequency of about The rotor is supported in lightly loaded This severe vibration arises from an

half the shaft rotational speed, which plain journal bearings and is reaching interaction between the bearings and the

shows a major increase in amplitude a rotational speed, equal to twice its rotor. The critical speed of the rotor

above a particular speed critical speed, when the major resonates with half speed vibration of the

vibration increase occurs bearings

Machines with plain journal bearings

generally have a maximum safe operating

speed of twice their first critical speed

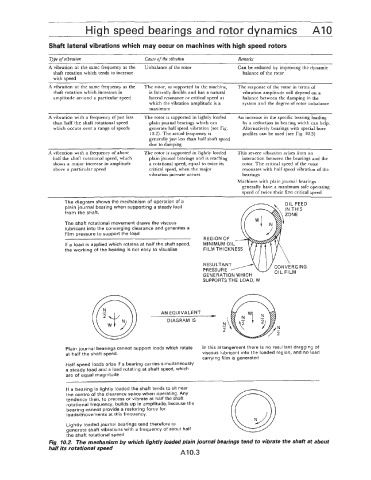

The diagram shows the mechanism of operation of a

plain journal bearing when supporting a steady load

from the shaft.

The shaft rotational movement draws the viscous

lubricant into the converging clearance and generates a

film pressure to support the load

REGION OF

If a load is applied which rotates at half the shaft speed, MINIMUM OIL

the working of the bearing is not easy to visualise FILM THICKNESS

\

RESULTANT~~JJ' CONVERGING

PRESSUR E OIL FILM

GENERATION WHICH

SUPPORTS THE LOAD, W

AN EQUIVALENT

P

DIAGRAM IS

N

- N

2 -

2

Plain journal bearings cannot support loads which rotate In this arrangement there is no resultant dragging of

at half the shaft speed. viscous lubricant into the loaded region, and no load

carrying film is generated

Half speed loads arise il a bearing carries simultaneously

a steady load and a load rotating at shaft speed, which

are of equal magnitude

If a bearing is lightly loaded the shaft tends to sit near

the centre of the clearance space when operating. Any

tendency then, to precess or vibrate at half the shaft

rotational frequency, builds up in amplitude, because the

bearing cannot provide a restoring force for

loadshnovements at this frequency.

Lightly loaded journal bearings tend therefore to

generate shaft vibrationis with a frequency of about half

the shaft rotational speed

Fig. 10.2. The mechanism by which lightly loaded plain journal bearings tend to vibrate the shaft at about

half its rotational speed

AI 0.3