Page 67 - The Tribology Handbook

P. 67

AI 1 Crankshaft bearings

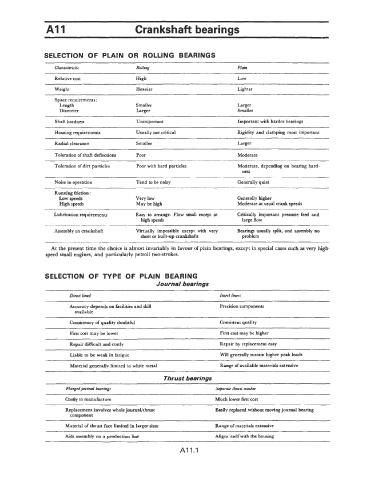

SELECTION OF PLAIN OR ROLLING BEARINGS

Charactnistic Rolling Plain

Relative cost High Low

Weight Heavier Lighter

Space requirements :

Length Smaller Larger

Diameter Larger Smaller

Shaft hardness Unimportant Important with harder bearings

Housing requirements Usually not critical Rigidity and clamping most important

Radial clearance Smaller Larger

~ ~~~ ~

Toleration of shaft deflections Poor Moderate

Toleration of dirt particles Poor with hard particles Moderate, depending on bearing hard-

ness

Noise in operation Tend to be noisy Generally quiet

Running friction :

Low speeds Very low Generally higher

High speeds May be high Moderate at usual crank speeds

Lubrication requirements Easy to arrange. Flow small except at Critically important pressure feed and

high speeds large flow

~ ~~ ~~~~~~~ ~

Assembly on crankshaft Virtually impossible except with very Bearings usually split, and assembly no

short or built-up crankshafts problem

At the present time the choice is almost invariably in favour of plain bearings, except in special cases such as very high-

speed small engines, and particularly petroil two-strokes.

SELECTION OF TYPE OF PLAIN BEARING

Journal bearings

Direct lined Insert liners

Accuracy depends on facilities and skill Precision components

available

~ ~~~~~~ ~ ~~

Consistency of quality doubtful Consistent quality

First cost may be lower First cost may be higher

Repair difficult and costly Repair by replacement easy

~ ~ ~~ ~

Liable to be weak in fatigue Will generally sustain higher peak loads

Material generally limited to white metal Range of available materials extensive

Thrust bearings

Flanged journal bearings Separate thrust washer

Costly to manufacture Much lower first cost

Replacement involves whole journal/thrust Easily replaced without moving journal bearing

component

Material of thrust face limited in larger sizes Range of materials extensive

Aids assembly on a production line Aligns itself with the housing

AI 1.1