Page 65 - The Tribology Handbook

P. 65

AI0 High speed bearing and rotor dynamics

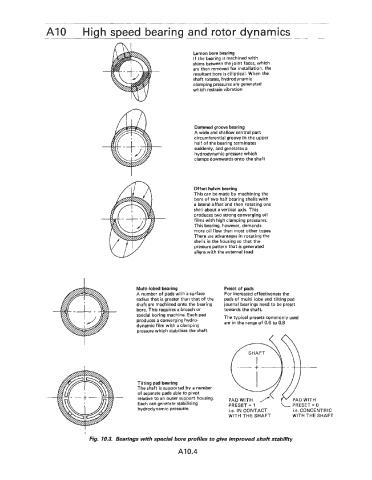

Lemon bore bearing

If the bearing is machined with

shims between the joint faces, which

are then removed for installation, the

resultant bore is elliptical. When the

shaft rotates, hydrodynamic

clamping pressures are generated

which restrain vibration

Dammed groove bearing

A wide and shallow central part

circumferential groove in the upper

half of the bearing terminates

suddenly, and generates a

hydrodynamic pressure which

clamps downwards onto the shaft

Offset halves bearing

This can be made by machining the

bore of two half bearing shells with

a lateral offset and then rotating one

shell about a vertical axis. This

produces two strong converging oil

films with high clamping pressures.

This bearing, however, demands

more oil flow than most other types.

There are advantages in rotating the

shells in the housing so that the

pressure pattern that is generated

aligns with the external load

Multi-lobed bearing Preset of pads

A number of pads with a surface For increased effectiveness the

radius that is greater than that of the pads of multi lobe and tilting pad

shaft are machined onto the bearing journal bearings need to be preset

bore. This requires a broach or towards the shaft.

special boring machine. Each pad The typical presets commonly used

produces a converging hydro- are in the range of 0.6 to 0.8

dynamic film with a clamping

pressure which stabilises the shaft

Tilting pad bearing

The shaft is supported by a number

of separate pads able to pivot

relative to an outer support housing.

Each can generate stabilising

hydrodynamic pressures i.e. IN CONTACT i.e. CONCENTRIC

WITH THE SHAFT WITH THE SHAFT

Fig. 10.3. Bearings with special bore profiles to give improved shaft stability

A10.4