Page 72 - The Tribology Handbook

P. 72

Crankshaft bearings AI 1

Locating devices

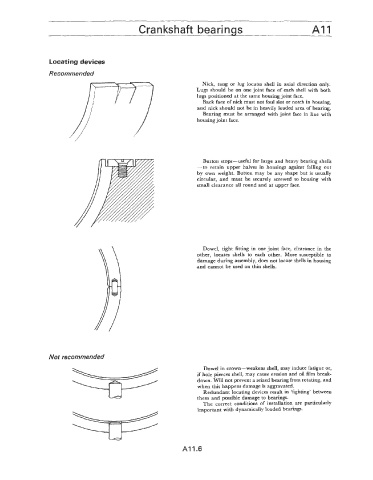

Recommended

Nick, tang or lug locates shell in axial direction only.

Lugs should be on one joint face of each shell with both

lugs positioned at the same housing joint face.

Back face of nick must not foul slot or notch in housing,

and nick should not be in heavily loaded area of bearing.

Bearing must be arranged with joint face in line with

housing joint face.

Button stops-useful for large and heavy bearing shells

-to retain upper halves in housings against falling out

by own weight. Button may be any shape but is usually

circular, and must be securely screwed to housing with

small clearance all round and at upper face.

Dowel, tight fitting in one joint face, clearance in the

other, locates shells to each other. More susceptible to

damage during assembly, does not locate shells in housing

and cannot be used on thin shells.

Not recommended

Dowel in crown-weakens shell, may induce fatigue or,

if hole pierces shell, may cause erosion and oil film break-

down. Will not prevent a seized bearing from rotating, and

when this happens damage is aggravated.

Redundant locating devices result in ‘fighting’ between

them and possible damage to bearings.

The correct conditions of installation are particularly

important with dynamically loaded bearings.

AI 1.6