Page 75 - The Tribology Handbook

P. 75

A12 Plain bearing form and installation

S ELECT1 0 N

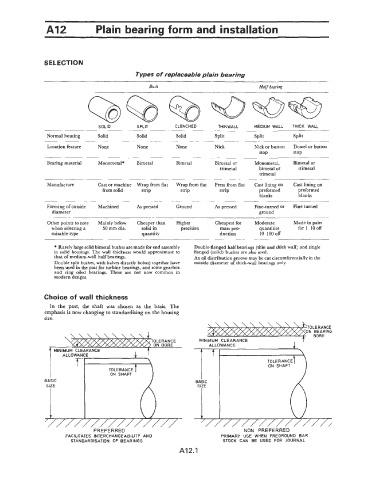

Types of replaceable plain bearing

Bush Half bearing

SOLID SPLIT CLENCHED THINWALL MEDIUM WALL THICK WALL

Normal housing Solid Solid Solid Split Split Split

Location feature None None None Nick Nick or button Dowel or button

stop stop

Bearing material Monometal* Bimetal Bimetal Bimetal or Monometal, Bimetal or

trimetal bimetal or trimetal

trimetal

Manufacture Cast or machine Wrap from flat Wrap from flat Press from flat Cast lining on Cast lining on

from solid strip strip strip preformed preformed

blanks blanks

Forming of outside Machined As pressed Ground As pressed Fine-turned or Fine turned

diameter ground

Other points to note Mainly below Cheaper than Higher Cheapest for Moderate Made in pairs

when selecting a 50 mm dia. solid in precision mass pro- quantities for 1-10 off

suitable type quantity duction 10-100 off

* Rarely large solid bimetal bushes are made for end assembly Double-flanged half bearings (thin and thick wall) and single

in solid housings. The wall thickness would approximate to flanged (solid) bushes are also used.

that of medium-wall half bearings. An oil distribution groove may be cut circumferentially in the

Double split bushes, with halves directly bolted together have outside diameter of thick-wall bearings only.

been used in the past for turbine bearings, and some gearbox

and ring oiled bearings. These are not now common in

modern designs.

Choice of wall thickness

In the past, the shaft was chosen as the basis. The

emphasis is now changing to standardising on the housing

size.

LERANCE

BEARING

BORE

MINIMUM CLEARANCE

MINIMUM CLEARANCE

ALLOWANCE A

T- TOLERANCET

TOLERANCE I I ON SHAFT

ON SHAFT

BASIC

SIZE n

.1 I

/

PREFERRED

FACILITATES INTERCHANGEABILITY AND PRIMARY USE WHEN PREGROUND BAR

STANDAROISATION OF BEARINGS STOCK CAN BE USED FOR JOURNAL

A12.1