Page 78 - The Tribology Handbook

P. 78

Plain bearing form and installation A12

Free spread

Thin- and medium-wall bearings are given a small Free spread may be lost when bearing heats up, particu-

amount of extra spread across the joint face to ensure that larly for copper and aluminium based lining alloys. The

both halves assemble correctly and do not foul the shaft in loss depends upon method of forming bearing, and thickness

the region of the joint when bolted up. of lining. Initial minimum free spread should exceed the

likely loss if bearing is required to be reassembled.

FypicaJ minimum free spread (mm)

Thin-wall aluminium

Outside diamettr or copper based Medium-wall white-

lining metal lining

100 4 1.0-2.0 0.2-0.5

~~ ~

300 ij 4.0-8.0 1 .o-2.0

Note: these figures are for guidance only and specific advice should

be obtained from the bearing manufacturers.

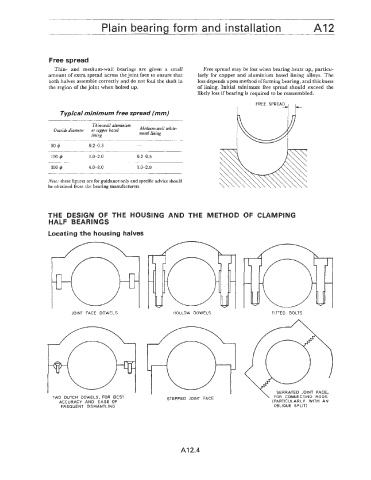

THE DESIGN OF THE HOUSING AND THE METHOD OF CLAMPING

HALF BEARINGS

Locating the housing halves

JOIN'I FACE DOWELS HOLLOW DOWELS FITTED BOLTS

SERRATED JOINT FACE,

TWO DUTCH DOWELS, FOR BEST STEPPED JOINT FACE \ FOR CONNECTING RODS

ACCURACY AND EASE OF (PARTICULARLY WITH AN

FREQUENT DISMANTLING OBLIQUE SPLIT)

A12.4