Page 79 - The Tribology Handbook

P. 79

A12 Plain bearing form and installation

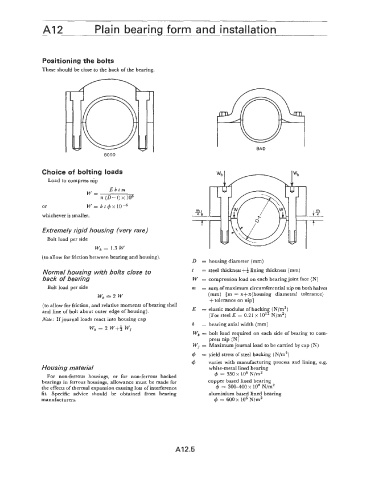

Positioning the bolts

These should be close to the back of the bearing.

I

BAD

GOOD

Choice of bolting loads

Load to compress nip

Ebtm

W=

.n (D-t) x IO6

or W = b t 4 x

whichever is smaller.

Extremely rigid housing (very rare)

Bolt load per side

wb = 1.3 w

(to allow for friction between bearing and housing)

D = housing diameter (mm)

Normal housing with bolts close to t = steel thickness+) lining thickness (mm)

back of bearing W = compression load on each bearing joint face (N)

Bolt load per side m = sum of maximum circumferential nip on both halves

Wb==2W (mm) [m = n+n(housing diametral tolerance)

+tolerance on nip]

(to allow for friction, and relative moments of bearing shell

and line of bolt about outer edge of housing). E = elastic modulus of backing (N/m2)

(For steel E = 0.21 x 10” N/m2)

Note: Ifjournal loads react into housing cap

Wb = 2 w+* wj b = bearing axial width (mm)

wb = bolt load required on each side of bearing to com-

press nip (N)

Wj = Maximum journal load to be carried by cap (N)

4 = yield stress of steel backing (N/m2)

4 varies with manufacturing process and lining, e.g.

Housing material white-metal lined bearing

For non-ferrous housings, or for non-ferrous backed 4 = 350x lo6 N/mZ

bearings in ferrous housings, allowance must be made for copper based lined bearing

the effects of thermal expansion causing loss of interference 4 = 300-400 x 1 O6 N/m2

fit. Specific advice should be obtained from bearing aluminium based lined bearing

manufacturers. 4 = 600~ lo6 N/m2

AI 2.5