Page 74 - The Tribology Handbook

P. 74

Crankshaft bearings AI 1

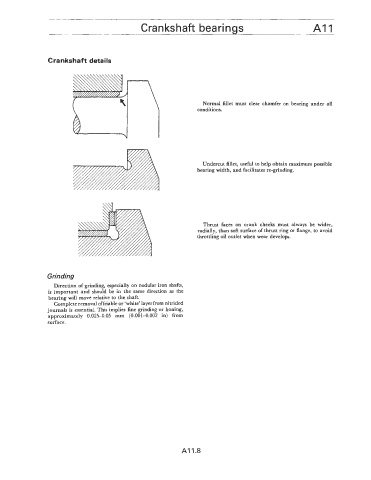

Crankshaft details

Normal fillet must clear chamfer on bearing under all

conditions.

Undercut fillet, useful to help obtain maximum possible

bearing width, and facilitates re-grinding.

Thrust faces on crank cheeks must always be wider,

radially, than soft surface of thrust ring or flange, to avoid

throttling oil outlet when wear develops.

Grinding

Direction of grinding, especnally on nodular iron shafts,

is important ;and should be in the same direction as the

bearing will move relative to the shaft.

Complete removal offriable or ‘white’ layer from nitrided

journals is essential. This implies fine grinding or honing,

approximately 0.025-0.05 mm (0.001-0.002 in) from

surface.

AI 1.8