Page 84 - The Tribology Handbook

P. 84

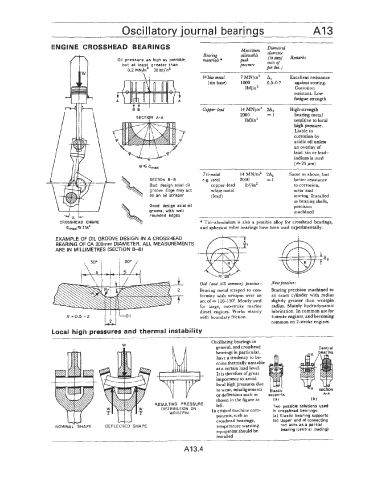

Oscillatory journal bearings A13

-~

ENGINE CROSSHEAD BEARINGS Dimtral

Bearing allowable clemmce

Oil pressure as high as possible, materials * peak (in am/ Remarks

but at least greater than presswe mmfl

0.2 MN/m2 JOIbf/in" pin dia.)

\

White metal JMN/m2 A, Excellent resistance

(tin base) 1000 0.5-0.7 against scoring.

Ibf/in2 Corrosion

resistant. Low

fatigue strength

Copper-led 14 MN/m2 2A2 High-strength

I

2000 =1 bearing metal

lbf/in2 sensitive to local

high pressure.

Liable to

corrosion by

acidic oil unless

an overlay of

lead-tin or lead-

indium is used

25

(e pm)

Tri-netal 14MN/m2 2A2 Same as above, but

SECTION 6-6 e.g. steel 2000 11 better resistance

Bad design axial oil copper-lead lbf/in2 to corrosion,

groove. Edge may act white metal wear and

as an oil scraper (lead) scoring. Installed

as bearing shells,

Good design axial oil precision

groove, with well machined

rounded edges

CROSSHEAD ENGINE * Tin-aluminium is also a possible alloy for crosshead bearings,

amax% t14~ and spherical roller bearings have been used experimentally.

EXAMPLE OF OIL GROOVE DESIGN IN A CROSSHEAD

BEARING Of: CA 300mm DIAMETER. ALL MEASUREMENTS

ARE IN MILL.IMETRES (SECTION 6-6)

Old (and still common) practice: New practice:

Bearing metal scraped to con- Bearing precision machined to

formity with wristpin over an an exact cylinder with radius

arc of 120-1 50". Mostly used slightly greater than wristpin

for large, two-stroke marine radius. MainIy hydrodynamic

diesel engines. Works mainly lubrication. In common use for

R =0.5 -2 with boundary friction. 4-stroke engines, and becoming

Lo-' common on 2-stroke engines.

Local high pressures and thermal instability

Oscillating bearings in

W

general, and crosshead Cent rat

bearings in particular,

have a tendency to be-

come thermally unstable

at a certairi load level.

It is therefore of great

importance to avoid

local high pressures due

to wear, misaIignments Elastic

or deflections such as supports A-A

shown in the figure at (a) (b)

RESULTING PRESSURE left.

Two possible solutions used

DISTRIBUTION ON In critical machine corn- in crosshead bearings:

WRISTPIN

w ponents, such as (a) Elastic bearing supwrts

crosshead bearings,

(b) Upper end of connecting

NOMINAL SHAPE DEFLECTED SHAPE temperature warning rod acts as a partial

equipment should be bearing [central loading)

installed

A13.4