Page 85 - The Tribology Handbook

P. 85

A13 Oscillatory journal bearings

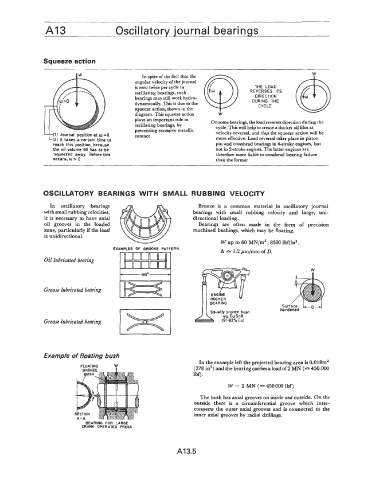

Squeeze action

IW In spite of the fact that the W

angular velocity of the journal

is zero twice per cycle in THE LOAD

oscillating bearings, such REVERSES ITS

bearings may still work hydro- DIRECTION

dynamically. This is due to the DURING THE

squeeze action, shown in the CYCLE

diagram. This squeeze action w

plays an important role in On some bearings, the load reverses direction during the

oscillating bearings, by cycle. This will help to create a thicker oil film at

preventing excessive metallic

LL(l) Journal position at w =O contact velocity reversal, and thus the squeeze action will be

L(2) It takes a certain time to more effective. Load reversal takes place in piston

reach this position. because pin and crosshead bearings in 4stroke engines, but

the oil volume % has to be not in 2-stroke engines. The latter engines are

‘squeezed’ away. Before this therefore more liable to crosshead bearing failure

occurs, w > 0 than the former

OSCILLATORY BEARINGS WITH SMALL RUBBING VELOCITY

In oscillatory bearings Bronze is a common material in oscillatory journal

with small rubbing velocities, bearings with small rubbing velocity and large, uni-

it is necessary to have axial directional loading.

oil grooves in the loaded Bearings are often made in the form of precision

zone, particularly if the load machined bushings, which may be floating.

is unidirectional. W up to 60 MN/m’; 8500 lbf/in2.

m

EXAMPLES OF GROOVE PATTERN A 1.2 pm/mm of D.

Oil lubricated bearing W

lE=q

Grease lubricated bearing

1x1 Usually bronze bush

eg. Cu Sn8

Grease lubricated bearing (91 -92% CU)

Example of floating bush

In the example left the projected bearing area is 0.018m2

F LOA1 ING W

(278 in’) and the bearing carries a load of 2 MN (== 450.000

lbf).

W = 2 MN (e 450000 lbf)

The bush has axial grooves on inside and outside. On the

outside there is a circumferential groove which inter-

connects the outer axial grooves and is connected to the

inner axial grooves by radial drillings.

BEARING FOR LARGE

CRANK OPERATED PRESS

A13.5