Page 90 - The Tribology Handbook

P. 90

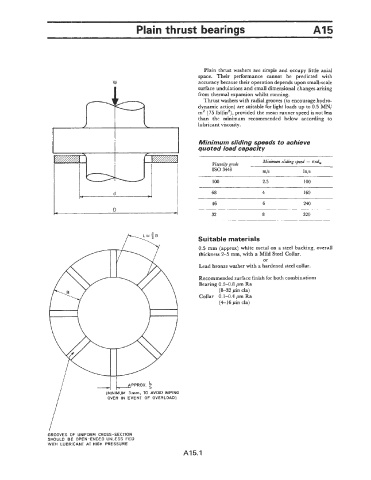

Plain thrust bearings A15

Plain thrust washers are simple and occupy little axial

space. Their performance cannot be predicted with

W accuracy because their operation depends upon small-scale

surface undulations and small dimensional changes arising

from thermal expansion whilst running.

Thrust washers with radial grooves (to encourage hydro-

dynamic action) are suitable for light loads up to 0.5 MN/

m2 (75 lbf/in2), provided the mean runner speed is not less

than the minimum recommended below according to

lubricant viscosity.

Minimum sliding speeds to achieve

quoted load capacity

Minimum sliding speed = nnd,

Viscosity grade

IS0 3448 mls in/s

100 2.5 100

68 4 160

46 6 240

32 8 320

Suitable materials

0.5 mm (approx) white metal on a steel backing, overall

thickness 2-5 mm, with a Mild Steel Collar.

or

Lead bronze washer with a hardened steel collar.

Recommended surface finish for both combinations

Bearing 0.2-0.8 pm Ra

(8-32 pin cla)

Collar 0.1-0.4 pm Ra

(4- 16 pin cla)

I OVER IN EVENT OF OVERLOAD)

GROOVES OF UNIFORM CROSS-SECTION

SHOULD BE OPEN-ENDED UNLESS FED

WITH LUBRICANT AT HIGH PRESSURE

AI 5.1