Page 92 - The Tribology Handbook

P. 92

Profiled pad thrust bearings A16

BEARING TYPE AND DESCRIPTION

W

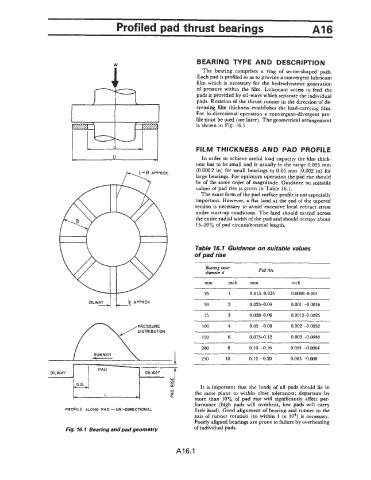

The bearing comprises a ring of sector-shaped pads.

Each pad is profiled so as to provide a convergent lubricant

film which is necessary for the hydrodynamic generation

of pressure within the film. Lubricant access to feed the

pads is provided by oil-ways which separate the individual

pads. Rotation of the thrust runner in the direction of de-

creasing film thickness establishes the load-carrying film.

For bi-directional operation a convergent-divergent pro-

file-must be used (see later). The geometrical arrangement

is shown in Fig. 16.1

I -- I FILM THICKNESS AND PAD PROFILE

In order to achieve useful load capacity the film thick-

ness has to be small and is usually in the range 0.005 mm

(0.0002 in) for small bearings to 0.05 mm (0.002 in) for

large bearings. For optimum operation the pad rise should

be of the same order of magnitude. Guidance on suitable

values of pad rise is given in Table 16.1.

The exact form of the pad surface profile is not especially

important. However, a flat land at the end of the tapered

section is necessary to avoid excessive local contact stress

under start-up conditions. The land should extend across

the entire radial width of the pad and should occupy about

15-20% of pad circumferential length.

Table 16.1 Guidance on suitable values

of pad rise

Bearing inner Pad rise

diameter d

mm inch mm inch

~~

25 1 0.015-0.025 0.00064.001

O'LWd APPROX 50 2 0.025-0.04 0.001 -0.0016

75 3 0.038-0.06 0.00I5-0.0025

~ ~~ ~

100 4 0.05 -0.08 0.002 -0.0032

150 6 0.075-0.12 0.003 -0.0048

- 200 8 0.10 -0.16 0.004 -0.0064

RUNNER

I 250 10 0.12 -0.20 0.005 4.008

OILWAY

I

It is important that the lands of ail pads should lie in

the same plane to within close tolerances; departure by

more than 10% of pad rise will significantly affect per-

formance (high pads will overheat, low pads will carry

PROFILE ALONG PAD -UNI-DIRECTIONAL little load). Good alignment of bearing and runner to the

axis of runner rotation (to within 1 in lo4) is necessary.

Poorly aligned bearings are prone to failure by overheating

of individual pads.

Fig. 16.1 Bearing and pad geometry

A16.1