Page 96 - The Tribology Handbook

P. 96

Profiled pad thrust bearings AI 6

LUBRICANT FEEDING

Lubricant should be directed to the inner diameter of

the bearing so that it flows radially outward along the oil-

ways. The outlet from the bearing housing should be

arranged to prevent oil starvation at the pads.

At high speed, churning power loss can be very signifi-

cant and can be minimised by sealing at the shaft and

runner periphery to reduce the area of rotating parts in P

contact with lubricant.

Lubricant feed rate

A lubricant temperature rise of 20°C in passing through

the bearing housing is typical. For a feed temperature of

50°C the housiing outlet temperature will then be 70”C,

which is satisfactory for general use with hydrocarbon

lubricants. The flow rate necessary for 20°C temperature

rise may be estimated by

Q= KH,

where K = 0.3 x lQ-’ for Qin m3/s, H in W

or K = 0.3 for Qin gal/min, H in h.p.

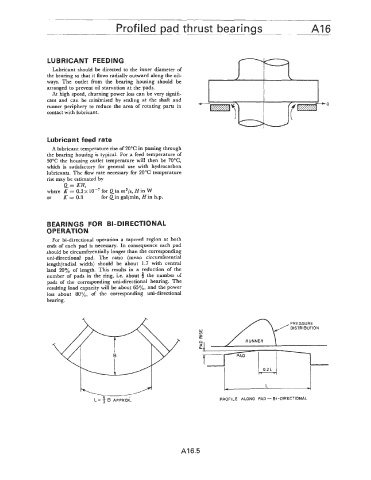

BEAR I N G S FOR B I - D I R ECTlO N A L

0 P E RAT1 0 N

For bi-directional operation a tapered region at both

ends of each pad is necessary. In consequence each pad

should be circumferentially longer than the corresponding

uni-directional pad. The ratio (mean circumferential

Bengthlradial vvidth) should be about 1.7 with central

land 20% of length. This results in a reduction of the

number of padls in the ring, i.e. about 3 the number of

pads of the corresponding uni-directional bearing. The

resulting load capacity will be about 65%, and the power

loss about BO”/,, of the corresponding uni-directional

bearing.

PRESSURE

DISTRIBUTION

DISTRIBUTION

W

u,

RUNNER

PROFILE ALONG PAD - BI -DIRECTIONAL

A16.5